(NEWS) PRESS RELEASE + DEMO VIDEO

Reliable Quality Assurance for Arc Welding During the Welding Process

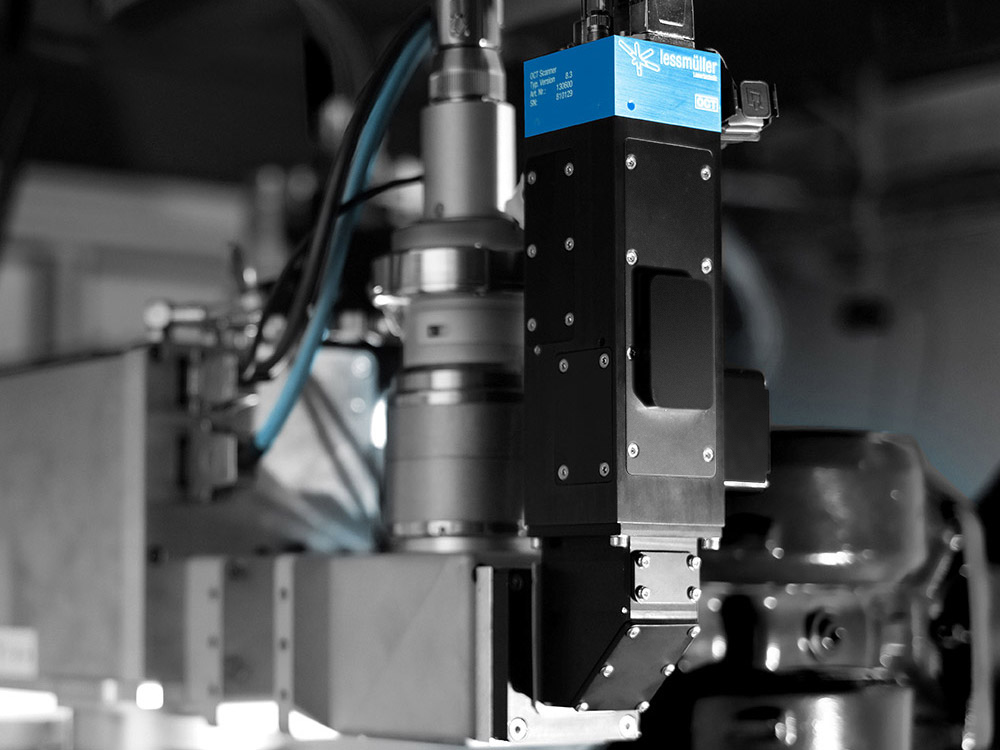

OCT technology enables precise seam tracking and inspection in a single pass

Munich, Germany, February 5, 2026 – Lessmüller Lasertechnik GmbH, one of the leading manufacturers of quality monitoring systems for industrial welding processes, is expanding its range of solutions to include automated weld seam inspection for gas metal arc welding (GMAW). The OCT 250 stand-alone sensor system uses optical coherence tomography (OCT) as a measurement method for continuous seam tracking and weld seam inspection in real time for automated GMAW processes. The advantages for users are obvious: OCT methods are significantly more precise than conventional camera technology, the effort required for subsequent quality control is reduced considerably and the userfriendly software also enables the evaluation and documentation of analysis data. Productivity increases and scrap can be measurably reduced …

COMPANY

for a better weld – because we put quality first!

Lessmüller Lasertechnik GmbH (Laser welding quality technologies), founded as a technology company in 1990, has gradually developed under the direction of company founder Eckhard Lessmüller and managing director Christian Truckenbrodt into the market leader for quality monitoring systems in laser welding processes.

By using photodiodes, camera systems with controlled extraneous light and optical coherence tomography, we can offer our customers the right solution for their tasks and thus contribute to the precise quality assurance of laser welding processes.

PRODUCT SOLUTIONS FOR LASER WELDING QUALITY

Patented and compatible

Whether seam finding or seam tracking, seam control, process monitoring or hairpin welding – Lessmüller Lasertechnik offers you unique and differentiated solutions for the quality assurance of your laser welding processes.

Our products are compatible and can be easily integrated into existing production systems. Ask us!

LASER WELDING APPLICATION AREAS

Versatile in use – the micro and macro cosmos of our product solutions

There are many different areas of application for monitoring laser welding processes. Find your industry here or a comparable application that corresponds to your production or is similar to your task in laser welding.

See how our technology could significantly improve your welding operations too.

You don’t find your business here? No problem…

CUSTOMERS

With complete satisfaction

NEWS

News and Events

PRESS RELEASE + DEMO VIDEO

Automotive Circle in Bad Nauheim

ACAT – Automated Calibration & Alignment Tool

Laser E-Mobility // Workshop 07./08.10.2025