WELDCHECK 4.1.

WELDCHECK 4.1.

Product features WELDCHECK

WELDCHECK 4.1.

Process monitoring and quality assurance for seam tracking laser welding

The WELDCHECK system detects the (emitted) process light from the welding process in a wide spectral range. It analyzes and compares the weld in real time with trained reference welds that have been judged to be good. If the system detects a deviation from the standard, the weld is considered defective. Tolerances can be set flexibly. The system is used for automated control to reduce inspection costs and increase output.

Typical detectable errors are:

- Deviation of laser energy

- Contamination of optics and protective glass

- Faulty focus position

- Joining gap too large

- Positioning error

- Change of welding depth

- Contamination of the surface

- Weld penetration

- Seam tracking laser welding

In use worldwide for more than 20 years, WELDCHECK enjoys unbroken demand. The current WELDCHECK 4.1 model offers a compact design, convenient operation and easy connection to fieldbuses.

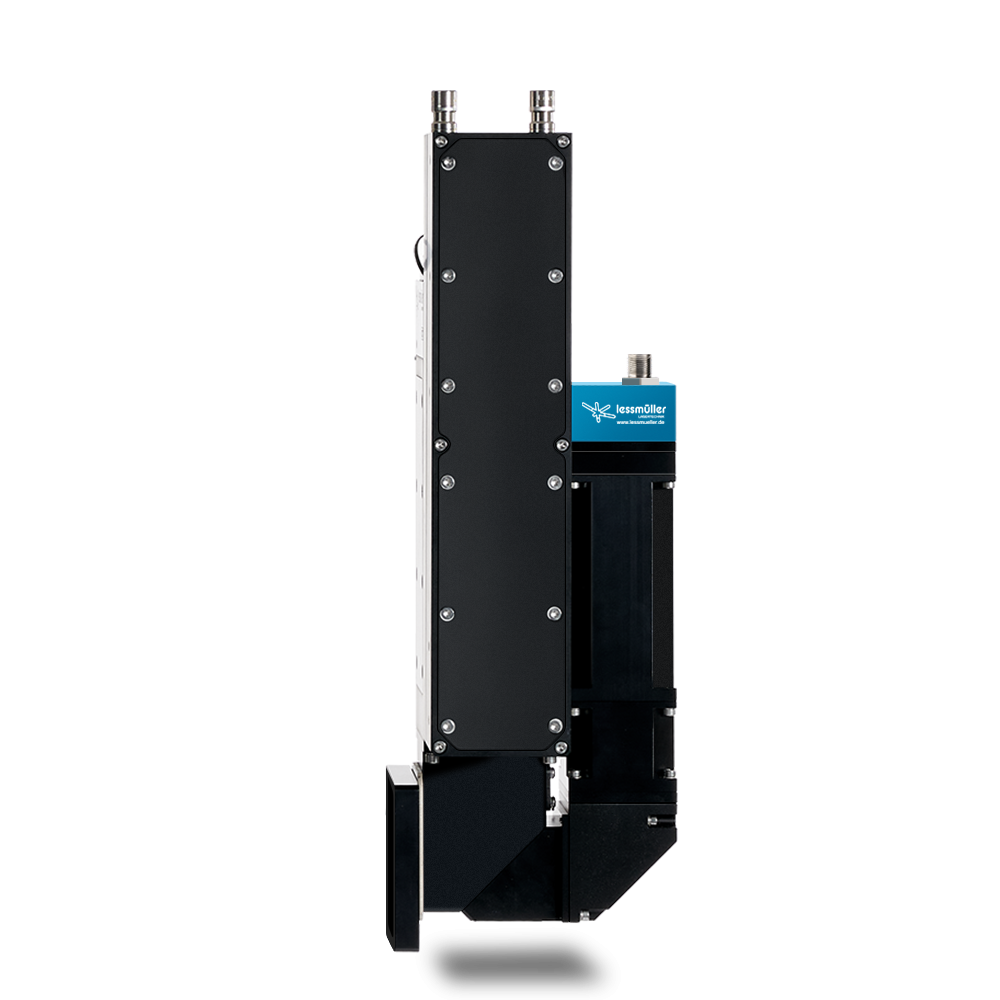

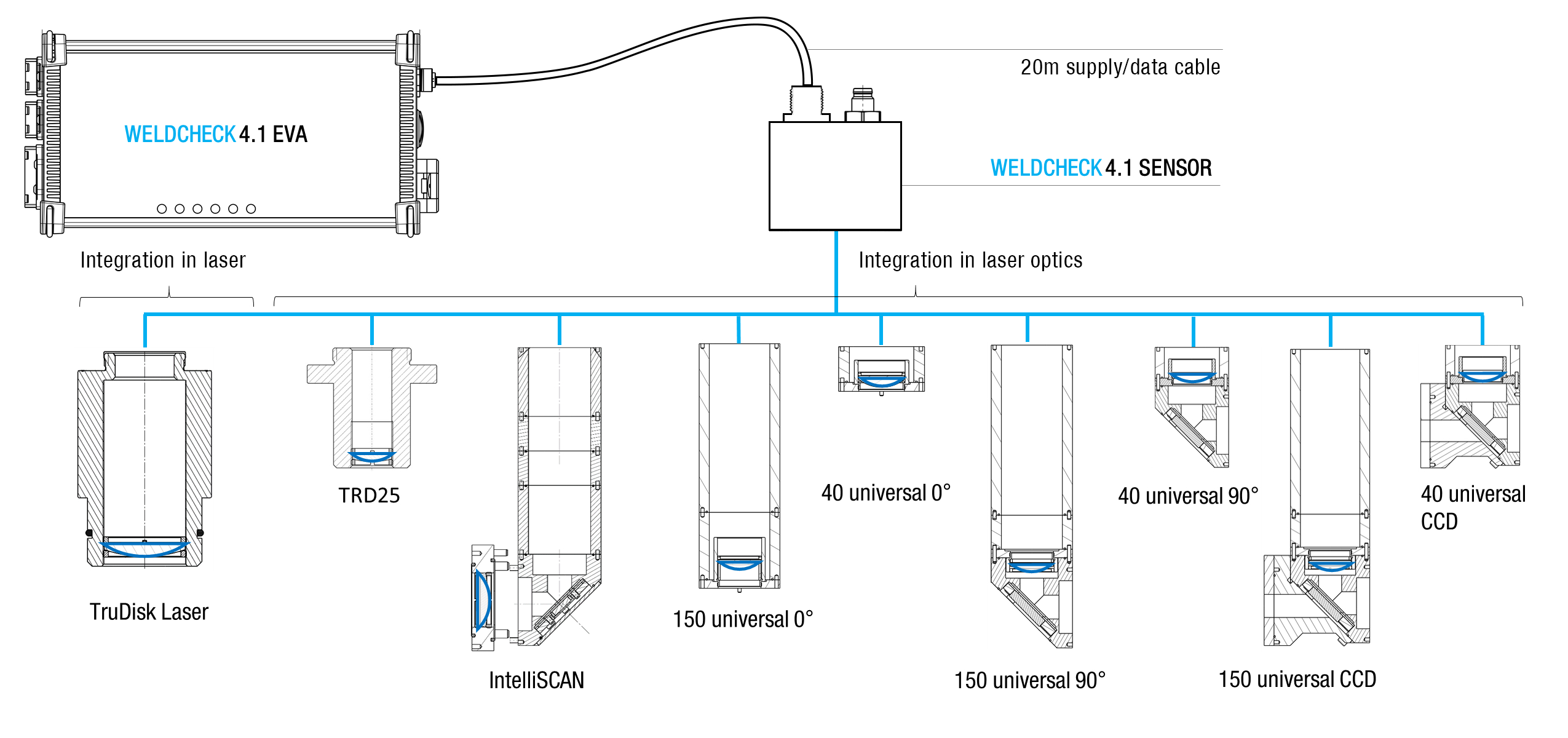

The system consists of a sensor and the evaluation unit (EVA).

Thanks to its compact design and by means of so-called ModSets (adaptation options), WELDCHECK 4.1 can be integrated in a space-saving and elegant manner in the beam source or in all common processing optics.

The following video shows how easy it is to put WELDCHECK 4.1 into operation, using integration into a Trumpf TruDisk laser as an example.

Advantages with WELDCHECK

Real-time monitoring of the welding process – Seam tracking laser welding

Immediate evaluation and online error detection linked to external fieldbus data

Wide monitoring spectrum (from 320 nm to 1650 nm)

For welding with CW or pulsed lasers (optional)

Easy installation on standard C-mount camera ports or directly into the laser source

Easy operation and parameterization

Practical QA solution for a wide variety of laser welding processes and materials

Compact, robust and cost-effective system with service-friendly design

APPLICATIONS

Here our WELDCHECK solutions have already proven themselves

WELDCHECK has established itself in virtually all manufacturing productions as a reliable and efficient tool for quality assurance of industrial laser welding processes. The technology here is simple but effective and at home in all industries.

Our WELDCHECK solutions have already proven themselves here …

Product Advise

.

Product solutions for seam tracking laser welding

Downloads

You don’t find your business here? No problem…

WELDCHECK 4.1.

WELDCHECK 4.1.