LSO

LSO

Product features LSO Laser welding monitoring system

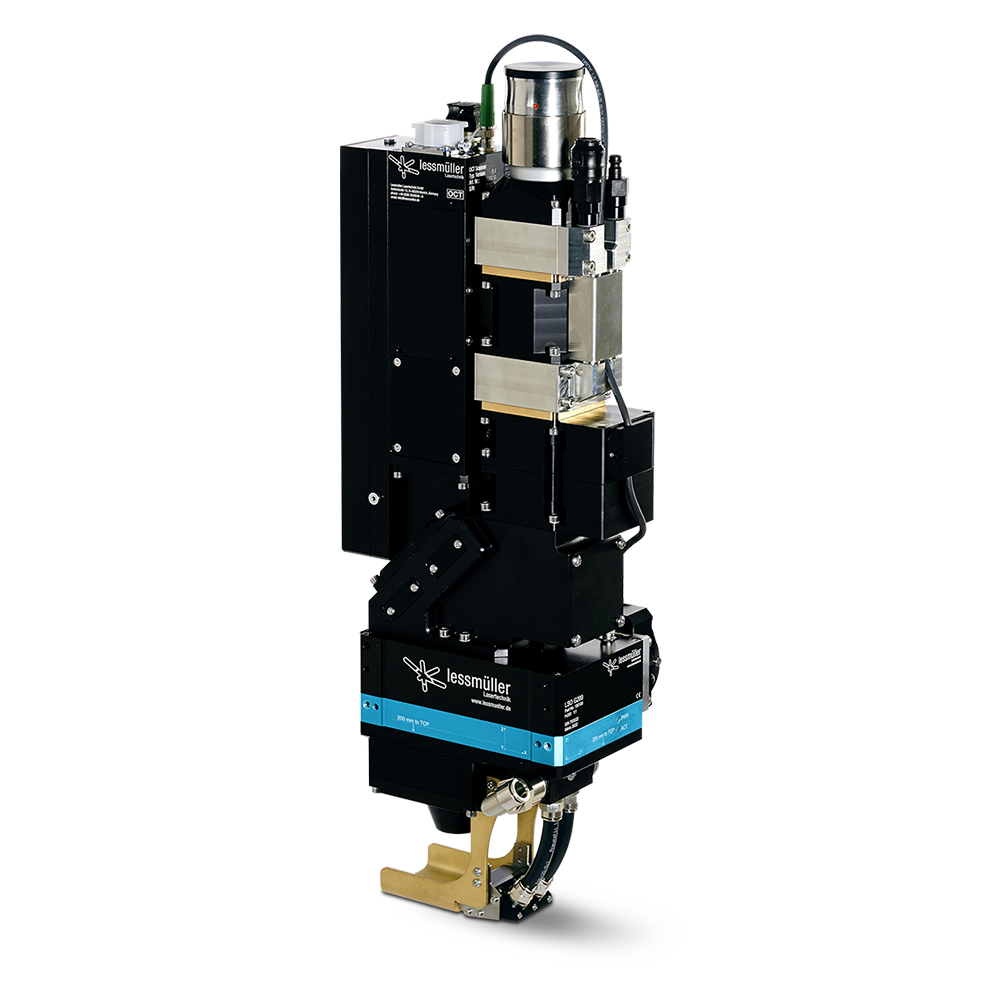

LASER WELDING OPTICS LSO

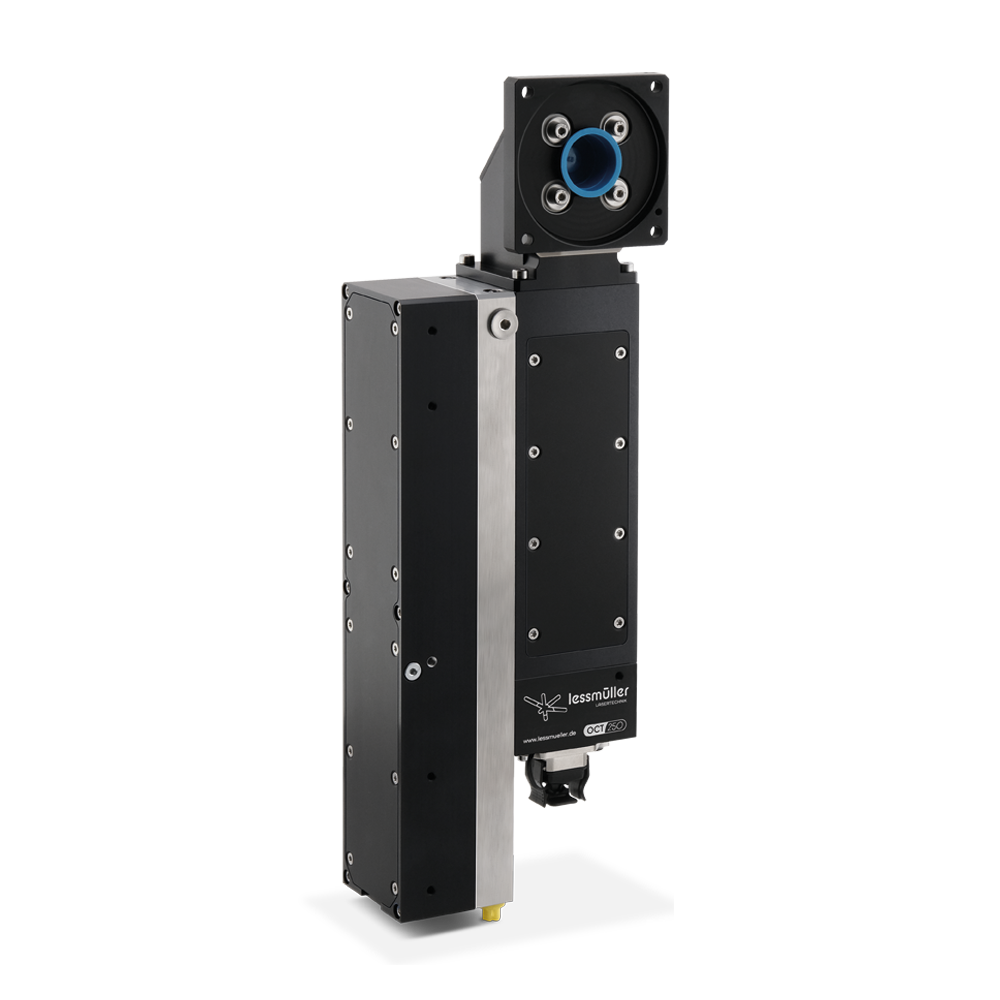

Lens Shifting Optics (LSO) for Laser Welding monitoring system

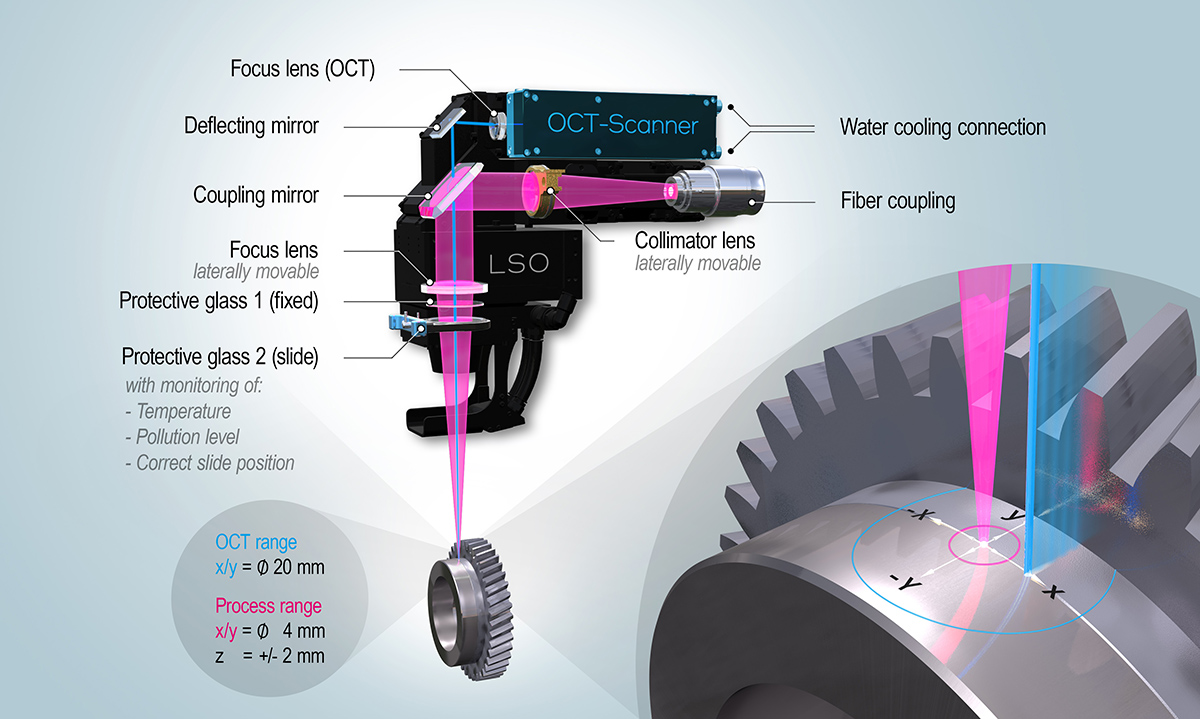

Lessmüller Lasertechnik, through LSO in combination with the latest sensor technology, OCT (Optical Coherence Tomography) -Laser welding monitoring system, brings a welding optics to the market that follows the weld seam and automatically compensates for positional tolerances.

The laser welding optics LSO offers:

- Precise and fast online correction of the weld position by detecting and tracing the weld joint

- Real-time control of the weld plane (autofocus)

- Possibility to measure the weld penetration depth (keyhole measurement) by OCT

- Measurement and evaluation of the finished weld seam

- Communication via standard fieldbuses (Profinet, Profibus, Ethercat, Devicenet)

The interaction of LSO and OCT in the video

The non-contact LSO system enables high-precision seam tracking as well as real-time process monitoring and quality assurance when welding with solid-state lasers.

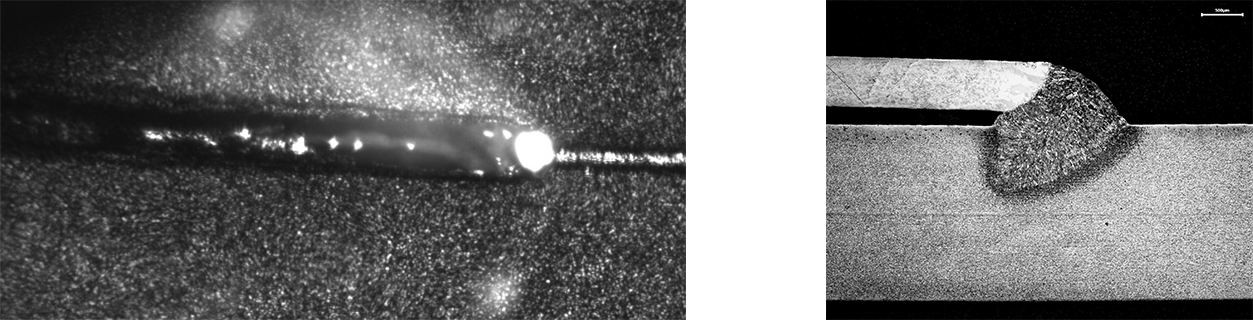

Real-time position control (left), gap bridging with LSO (right)

Due to the seamless integration of OCT into the welding optics, the user receives a compact overall system as a black box that can correct autonomously and ensures optimum welding quality.

During the active welding process, the system uses optical coherence tomography (OCT) to ensure precise position determination with the accuracy of 0.05 mm. The position of the weld joint is determined approx. every 10 ms and tracked by lateral lens shift.

When the distance from the component to the LSO changes, the optimum focus position is determined and regulated in real time by the axial lens shift.

Quality assurance algorithms proven in the series production process monitor both position control and the welding process as well as the weld seam and report critical weld seams to the higher-level system control.

If required, the LSO (Laser welding monitoring system) can be expanded with Lessmüller’s WELDCHECK system to maximize functionality.

Advantages with LSO

Precise welding with solid-state lasers up to 6 kW

Compact and lightweight system; easy integration into different motion systems

Reduced positioning times thanks to fast adjustable focusing lens for active control of focus position and welding position

Fast setup of the TCP (Tool Center Point) with integrated pilot lasers

Temperature monitoring of protective glass, focus and collimation lens

Intelligent self-diagnosis and optimization (Industry 4.0)

Expandable with WELDCHECK (diode-based quality assurance system)

Advantages with OCT

Fast and accurate seam tracking with different seam shapes

Automatic adjustment of the system to the focus position

Real-time measurement of weld penetration depth

Flexible adjustment of the scanning area for active seam tracking and quality assessment

Online detection and immediate reporting of welding and seam defects

Precise process and quality monitoring through online documentation of measurement data and process parameters

APPLICATIONS

Here our OCT solutions have already proven themselves

OCT has established itself in practically all manufacturing productions as an optimal and comprehensive tool for quality assurance of industrial laser welding processes. Our laser welding monitoring system.

The technology for laser welding monitoring system is trend-setting and is already considered the standard solution par excellence in many industries.

And the development continues: For example, Lessmüller Lasertechnik is supporting the Friedrich Alexander University (FAU) Nuremberg-Erlangen in the KIKoSA research project to optimize laser welding processes through the use of artificial intelligence (AI).

Our OCT solutions have already proven themselves here …

Product Advise

.

Product solutions for laser welding monitoring system

Downloads

You don’t find your business here? No problem…

LSO

LSO