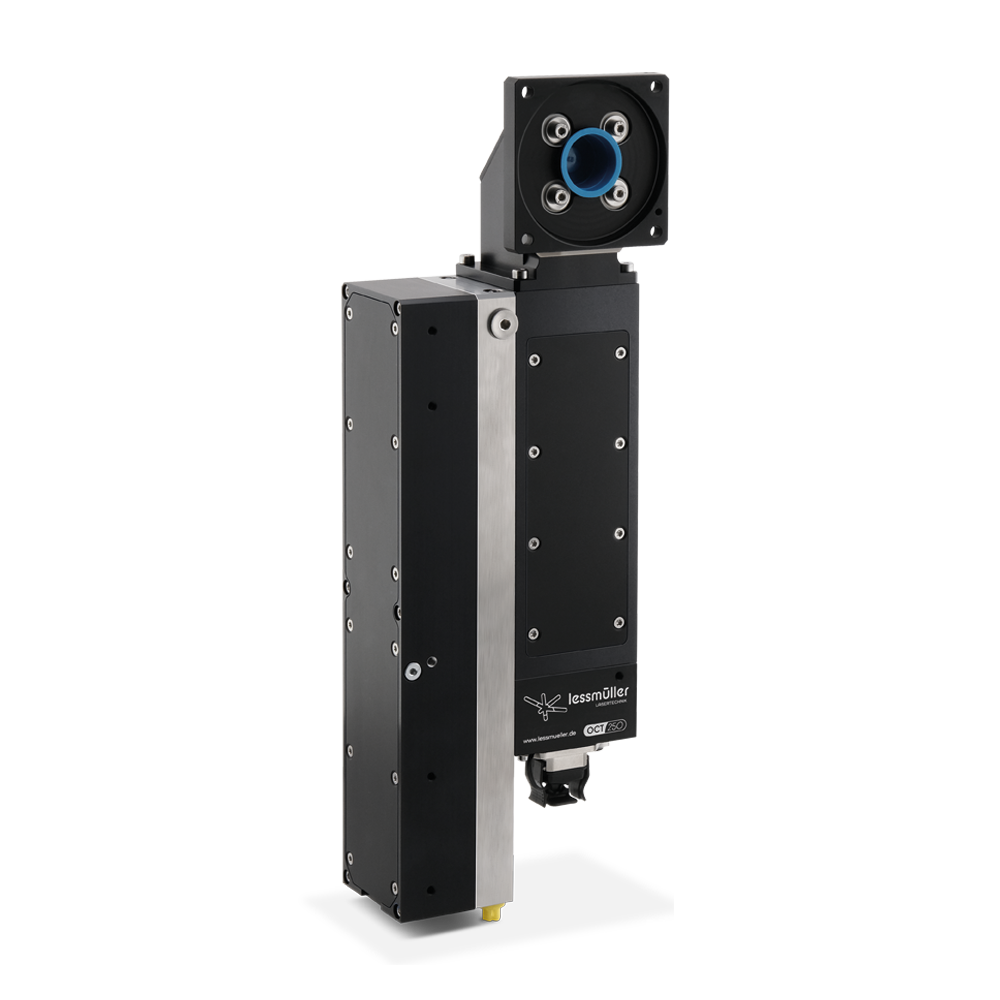

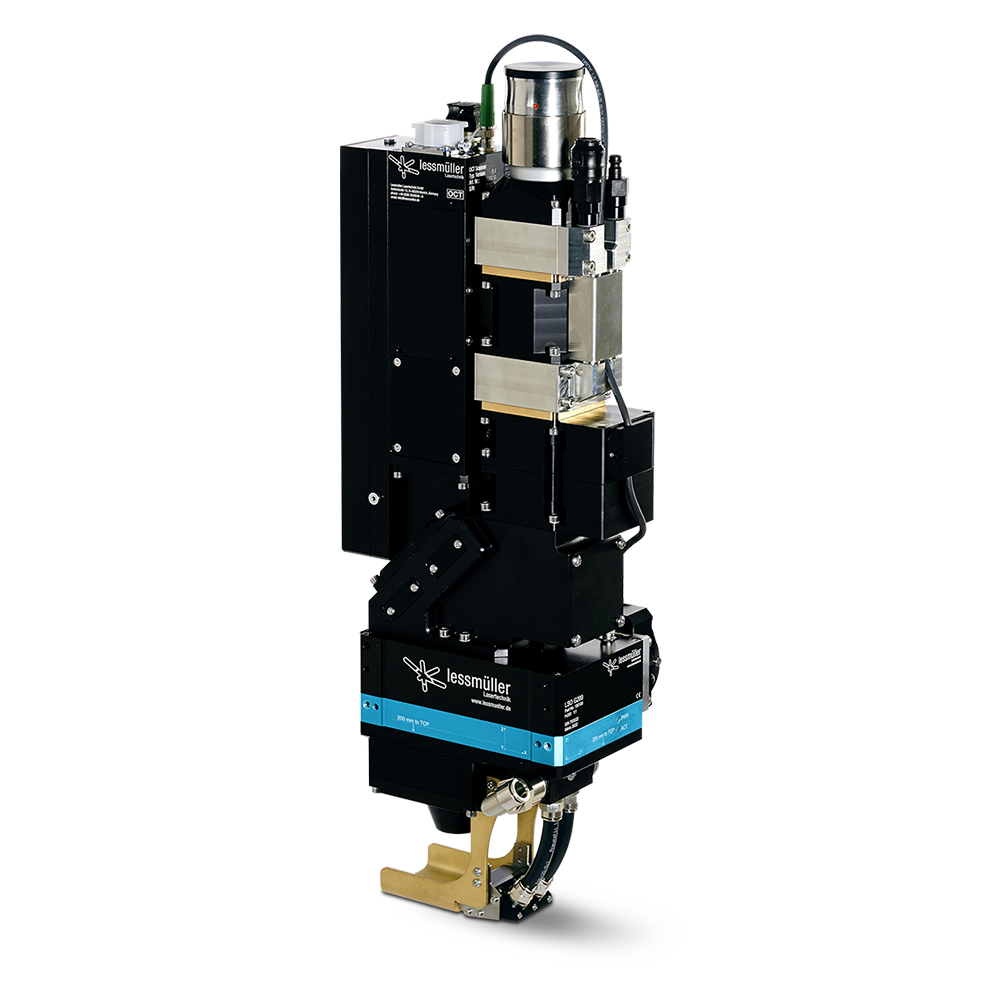

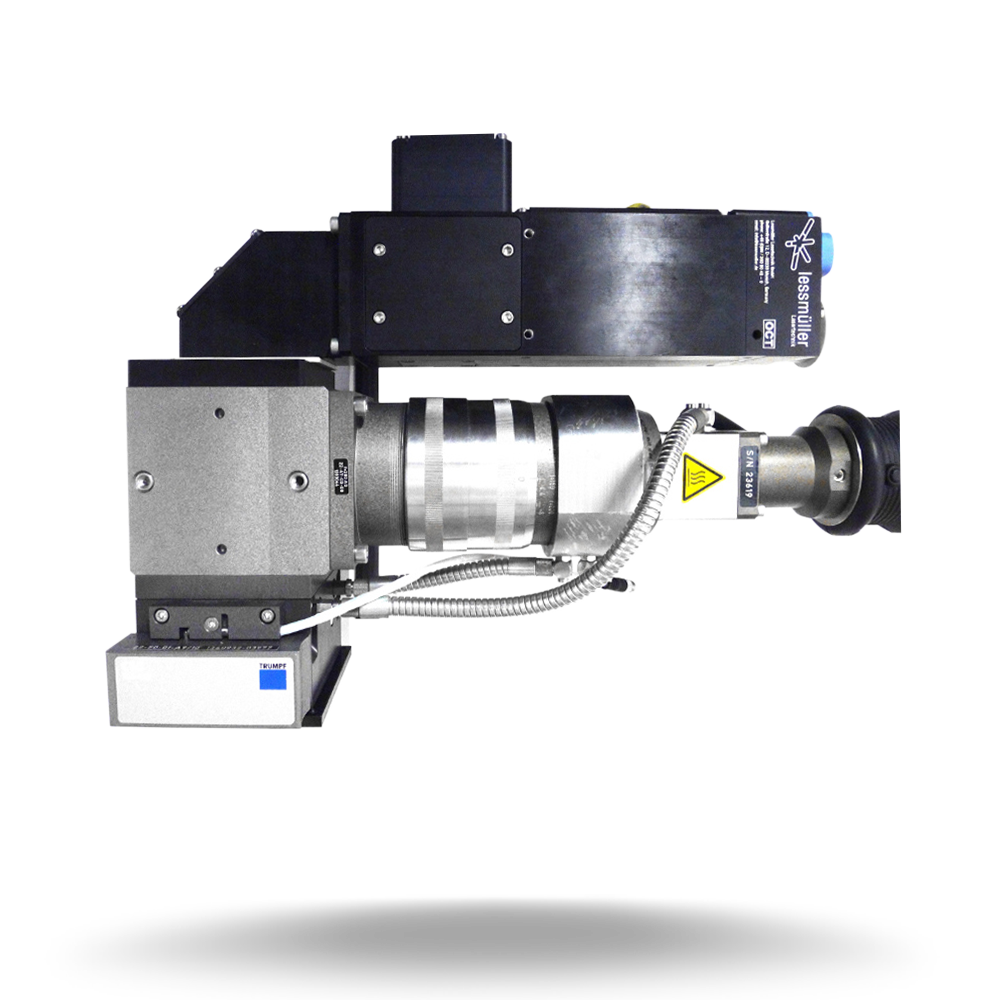

REMOTE LASER-WELDING OPTIC OCTSCAN 2.5

OCT 250 integrated 2.5D scanner-based welding optic for remote welding applications

With the OCTSCAN 2.5 system Lessmüller Lasertechnik provides a complete solution that seamlessly integrates OCT analytics (optical coherence tomography) into remote laser welding applications.

OCTSCAN 2.5 enables seam tracking as well as measuring the keyhole depth in real time. The possibility to analyze the topography of the weld (seam inspection) after processing demonstrates the full capabilites of this tool for demanding applications.

Communication with the system controller takes place via Ethernet fieldbus protocols, making the integration of remote welding optics comparable to the integration of fixed optics.

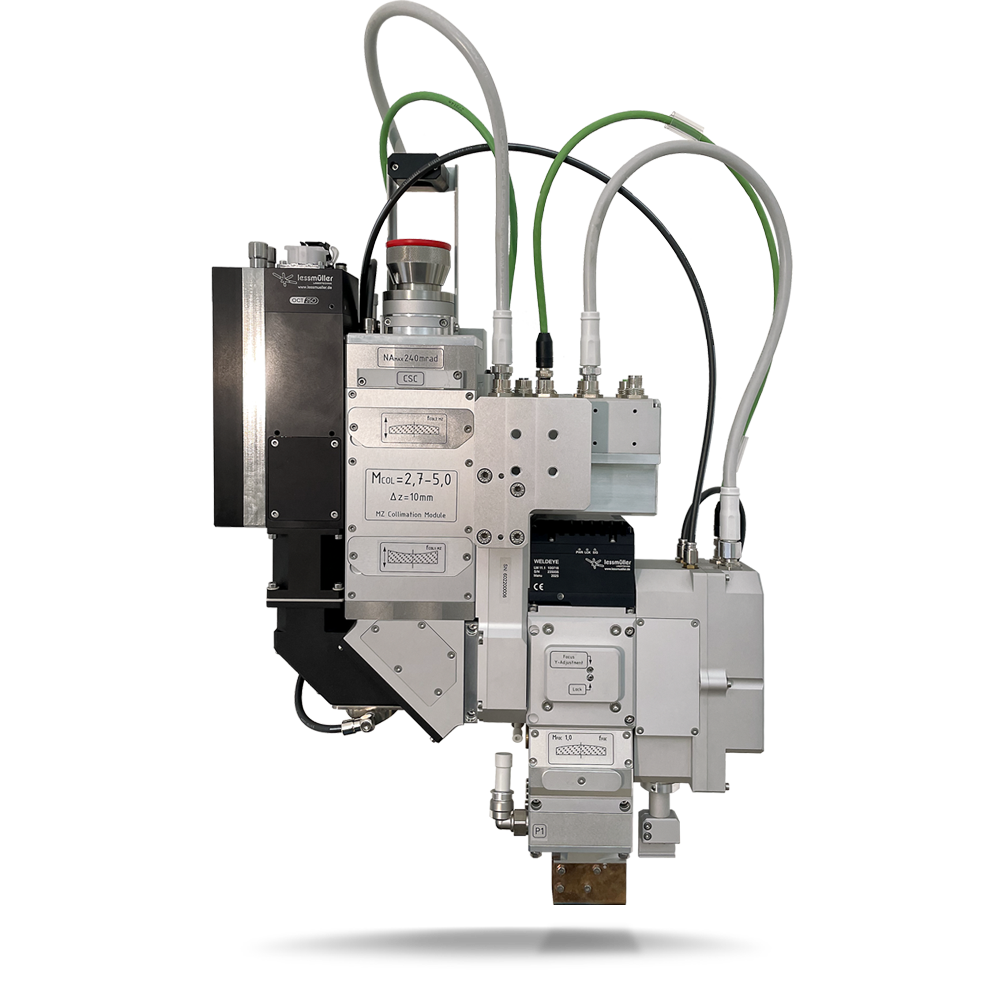

The welding optics realise direct control of the laser processing head and the OCT system in order to realise a highly dynamic OCT measurement synchronised with the laser process. The synchronised tracking of the OCT measurement means that measurement data is continuously available in the keyhole. This ensures precise seam tracking and OCT measurement of the welding depth even when the scanner optics are wobbling.

Details are described in the following publication: https://lia.scitation.org/doi/10.2351/7.0000898

The OCTSCAN 2.5 laser welding optics offers:

- Option to measure the welding depth (keyhole measurement) using OCT during the welding process

- Measurement of the component position before the process in order to optimise the seam tracking in the process

- Precise and fast online correction of the welding position by recognising and determining the course of the weld joint

- Real-time control of the welding level (autofocus)

- Measurement of the topography and assessment of the solidified weld

Height Tracker

Oscillation Compensation

The communication with the main control of the laser cell is realized by ethernet-based fieldbus protocols, enabling a straight forward integration of the remote optic with comparable effort like a fixed optics.

The welding optic is realized with direct control of the laser processing head and the OCT system, enabling a highly dynamic OCT measurement synchronous with the laser process. This synchronous control allows OCT analysis of the keyhole depth. Due to this integration even during wobble movement of the laser processing optics a precise seam tracking and keyhole measurement can be realized. Please find further detail in the publication https://lia.scitation.org/doi/10.2351/7.0000898

The laser welding optic OCTSCAN 2.5 provides:

- Keyhole measurement by OCT analytics during the welding process

- Determination of the exact position of the work piece prior to the welding process

- Precise an fast online correction of the welding position by seam tracking

- Real time adjustement of the focus position based on the OCT measurement (auto-focus)

- Analysis of the topography of the finished weld seam (POST-measurement)

The complete system can be parametrized and initialized utilizing the established Lessmüller Software. The measured data can directly be analysed and also be logged for later evaluation and quality control. By this even long term analysis of the process stability and fluctuations can be established.

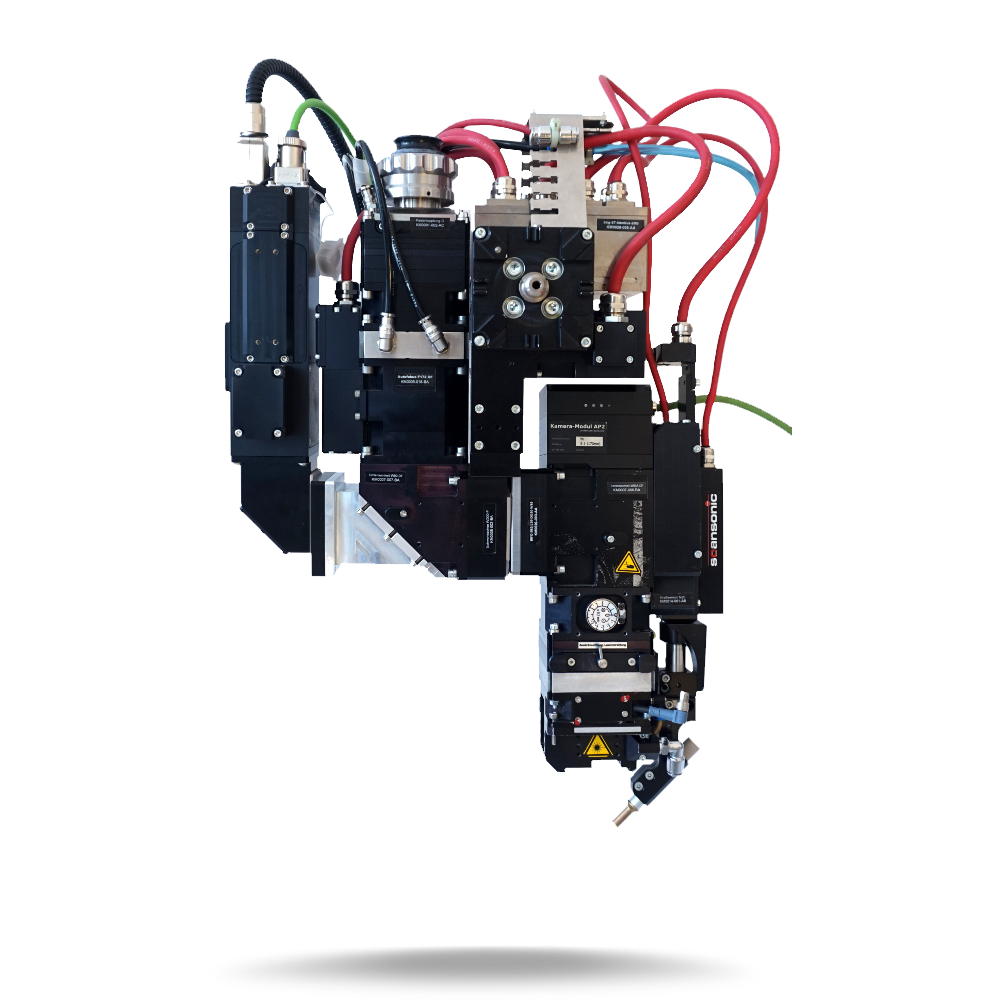

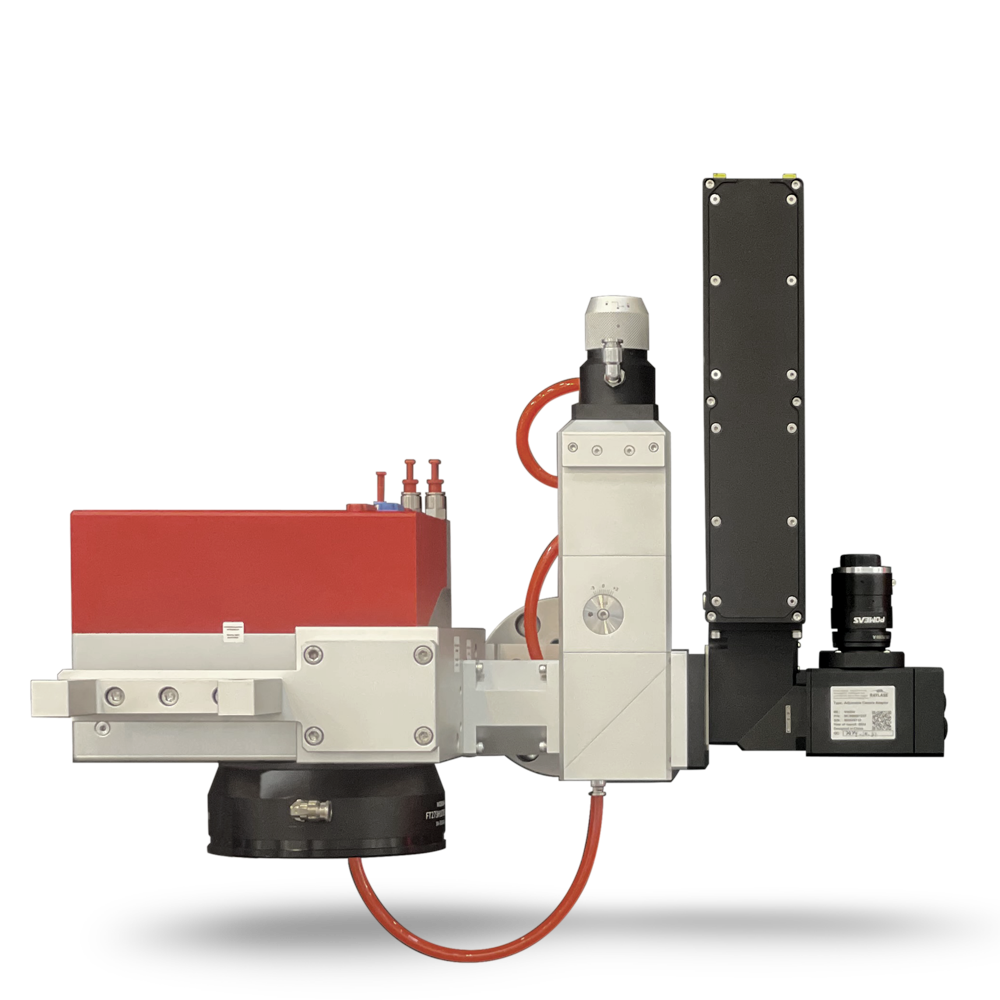

The performance of the OCTSCAN 2.5 system can be extended using Lessmüller’s WELDCHECK sensor by Lessmüller or by integrating custom camera solutions for a coaxial observation.

Advantages using the OCTSCAN 2.5

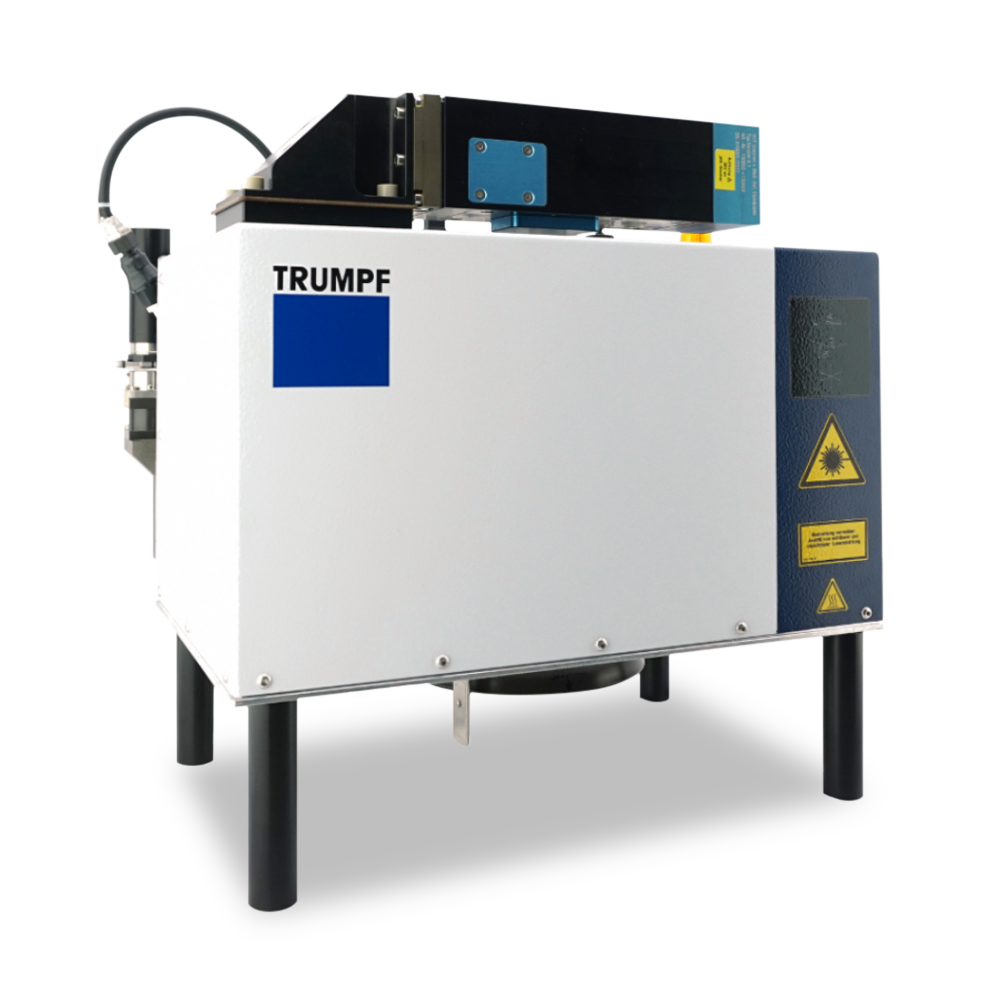

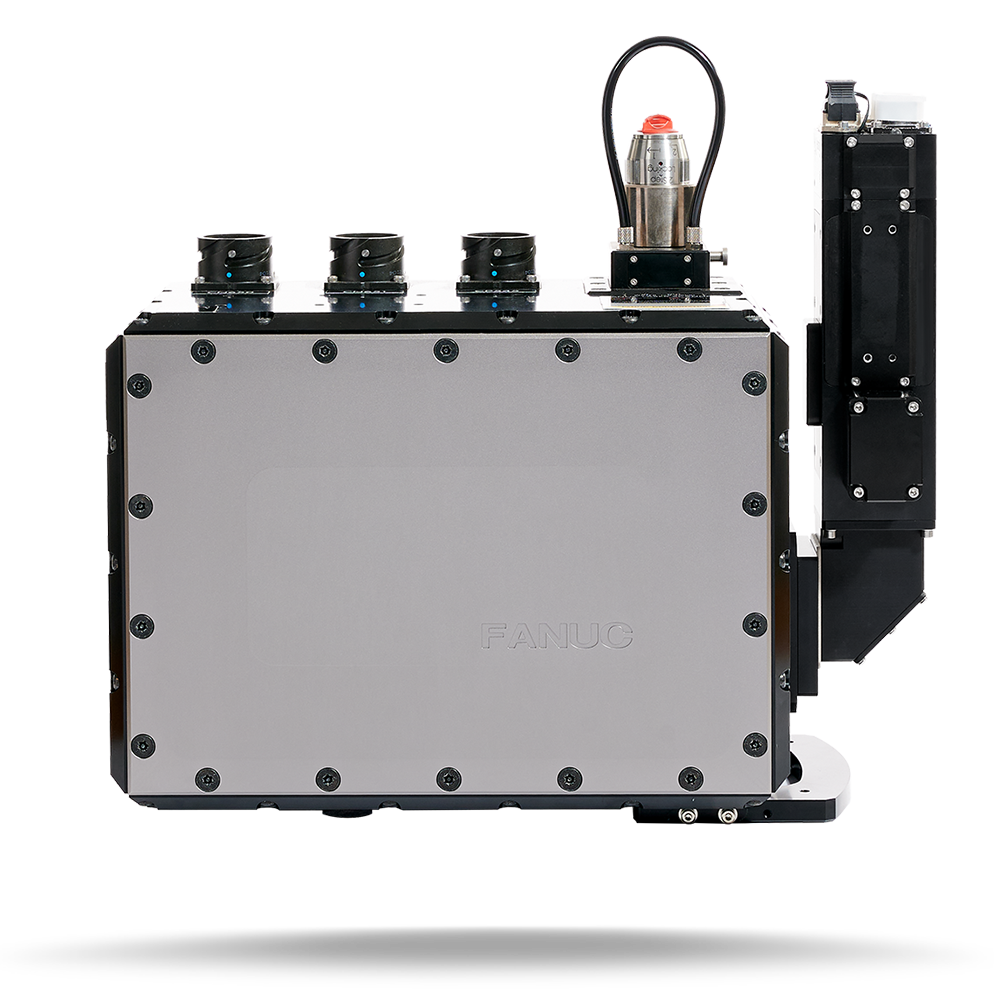

Efficient remote welding using solid state lasers and F-theta scanning optics

Full OCT-performance for Pre-, In- und Post-analytics also during wobble welding applications and for tight radii at high speeds

Recognition of geometric features on the part to exactly position the processing laser relative to the work piece

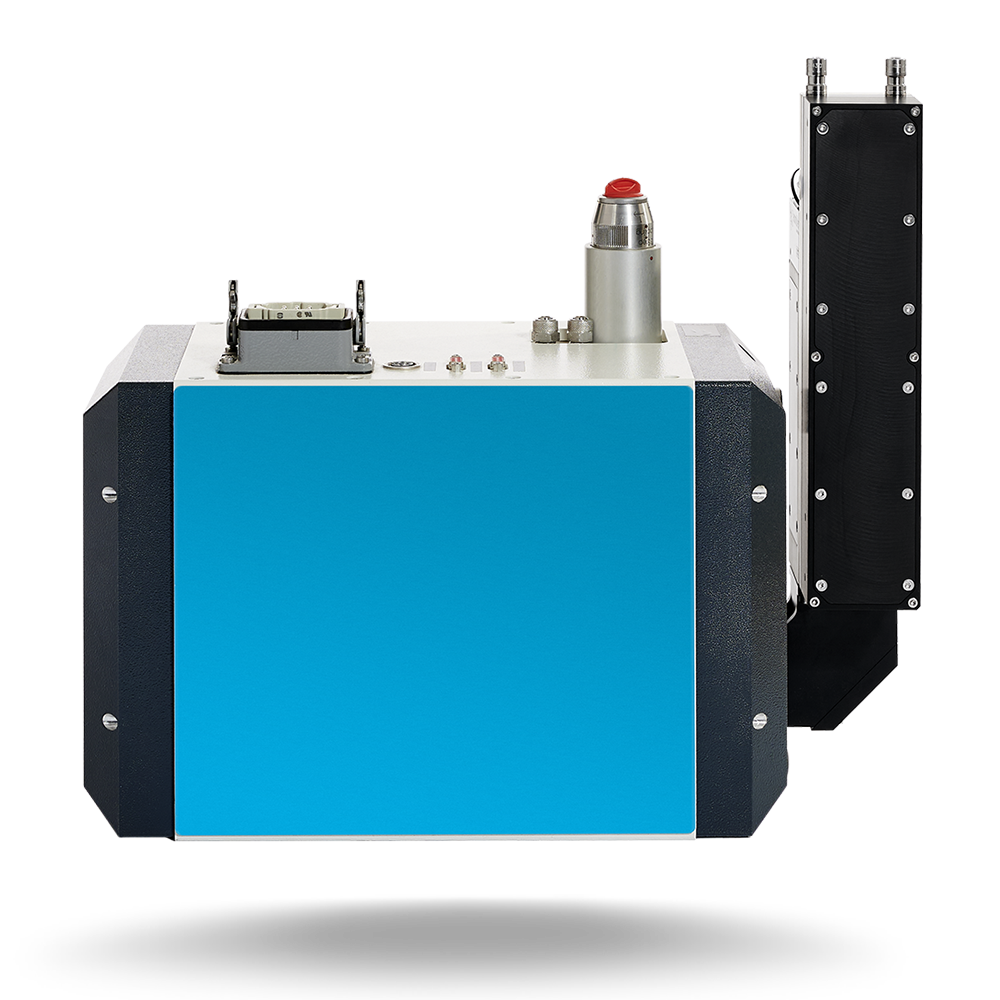

Fast focussing lens for controlling the focus position

Extensible with WELDCHECK (diode-based quality assurance system)

Fast calibration of the TCP (Tool Center Point) and confirmation of the focus position utilizing the optional ACAT system

Advantages using OCT

Real-time measurement of the key hole depth and seam inspection based on one coaxial sensor system

Fast and precise seam tracking of various seam configurations as well as seam tracking in various directions and orientations

Robust and validated recognition and evaluation algorithms for various surface features and seam geometries

Online recognition and immediate communication of weld and seam failures

Measurement technology independent of process and other stray lights

APPLICATIONS

Our OCT solutions have already proven themselves here

OCT has established itself in practically all manufacturing productions as an optimal and comprehensive tool for quality assurance of industrial laser welding processes. The technology is trend-setting and is already considered the standard solution par excellence in many industries.

And the development continues: For example, Lessmüller Lasertechnik is supporting the Friedrich Alexander University (FAU) Nuremberg-Erlangen in the KIKoSA research project to optimize laser welding processes through the use of artificial intelligence (AI).

If you would like to learn more about the technical basics of OCT, we recommend the guidelines of the Association of German Engineers (VDI).

Our OCT solutions have already proven themselves here …

Product advice

.

Laser welding product solutions

Downloads

OCT for scanner and fixed optics

You don’t find your business here? No problem…