Hairpin welding

HAIRPIN WELDING

Precise welding thanks to OCT

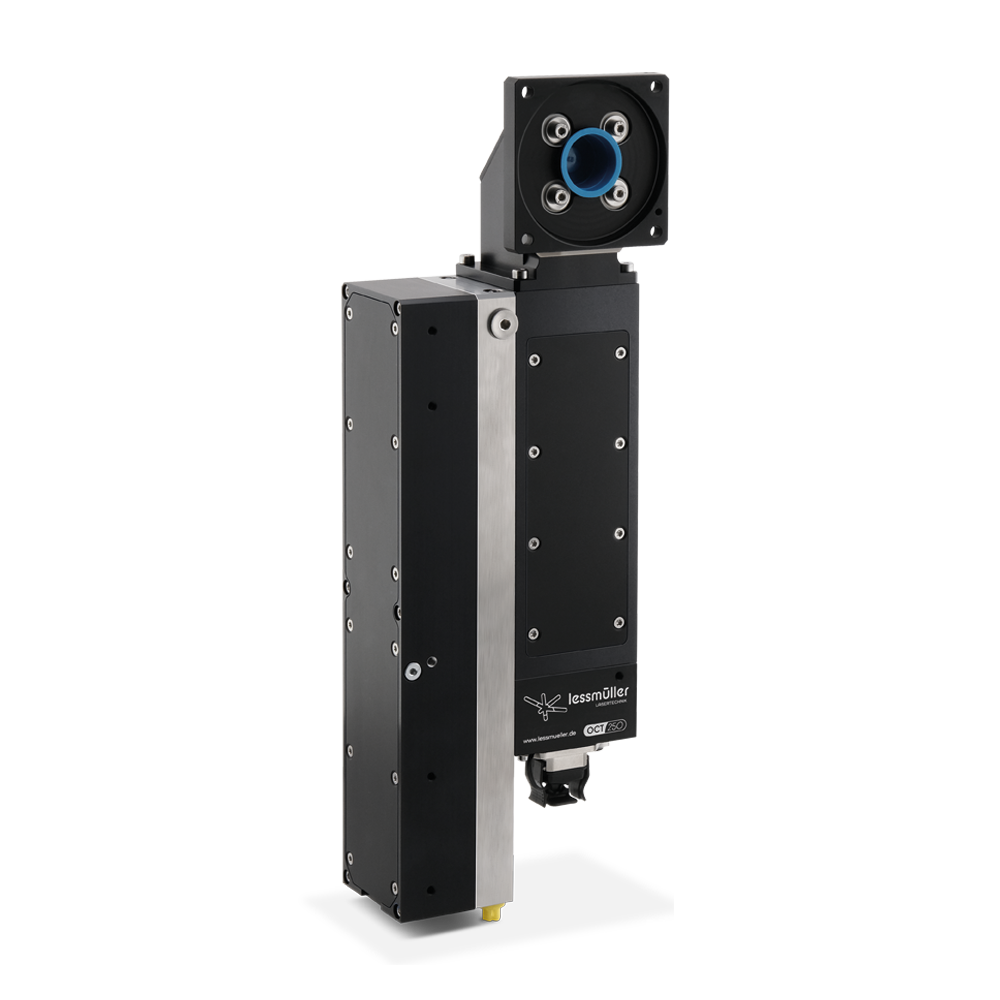

The OCT system from Lessmüller Lasertechnik, which is based on optical coherence tomography, offers specially developed functions for hairpin welding laser.

An exact positioning of the TCP (Tool Center Point), for example, is crucial for an optimal welding result. Differences in height between the hairpins or irregularities from previous process steps (e.g. cutting) can lead to poor welding results or even make the stator unusable.

OCT records the height profile and the exact position of the hairpin pairs in the room before welding and forwards this information to the system control. Thus, the TCP of the processing laser can be placed optimally. If the differences in height between the hairpins are too large or if there are other tolerance violations, the welding process is aborted before a faulty weld occurs. This reduces waste and significantly lowers the associated costs.

OCT measures the contour of the solidified weld bead after welding. In this way, flaws in the beads are automatically detected. The bead volume can be approximately determined by comparing it with the measurement before welding. A possible loss of material that impairs the conductivity of the weld is reliably detected.

All measurement and evaluation data of the OCT system can be saved and thus enable complete traceability.

Hairpins quality check with three OCTscans: top row – nearly identical OCT surface profiles on the same weld indicate good weld quality; bottom row – different shapes of OCT surface profiles on the same weld indicate poor weld quality.

At home in many industries

You don’t find your business here? No problem…