Car body construction

Car body construction

PROCESS MONITORING CAR BODY CONSTRUCTION

Safe monitoring and control of the welding processes with sensor technolgy for laser welding monitoring

The automotive industry is the technological trendsetter in the manufacturing industry. Fully automatic, fast laser welding of various components in unattended operation without time-consuming set-up is the rule and not the exception.

Laser welding systems must work independently, especially with large quantities. Despite the high welding speed, the laser beam has to hit the welding joint precisely. Changes in the process parameters can affect the geometry and properties of a welded joint. This can impair the mechanical behavior of the welded component and lead to malfunctions. Therefore, the monitoring and control of the laser welding process is crucial to ensure the quality of the weld. Accelerated manufacturing also requires new monitoring capabilities to improve laser processing through the use of innovative laser monitoring technology.

In general, we see three laser welding processes in production:

- Laser welding or laser soldering with filler wire and tactile seam tracking sensors

- Laser welding with fixed optics without filler wire

- Laser welding with remote optics to increase the welding speed and/or to weld more complex welding geometries.

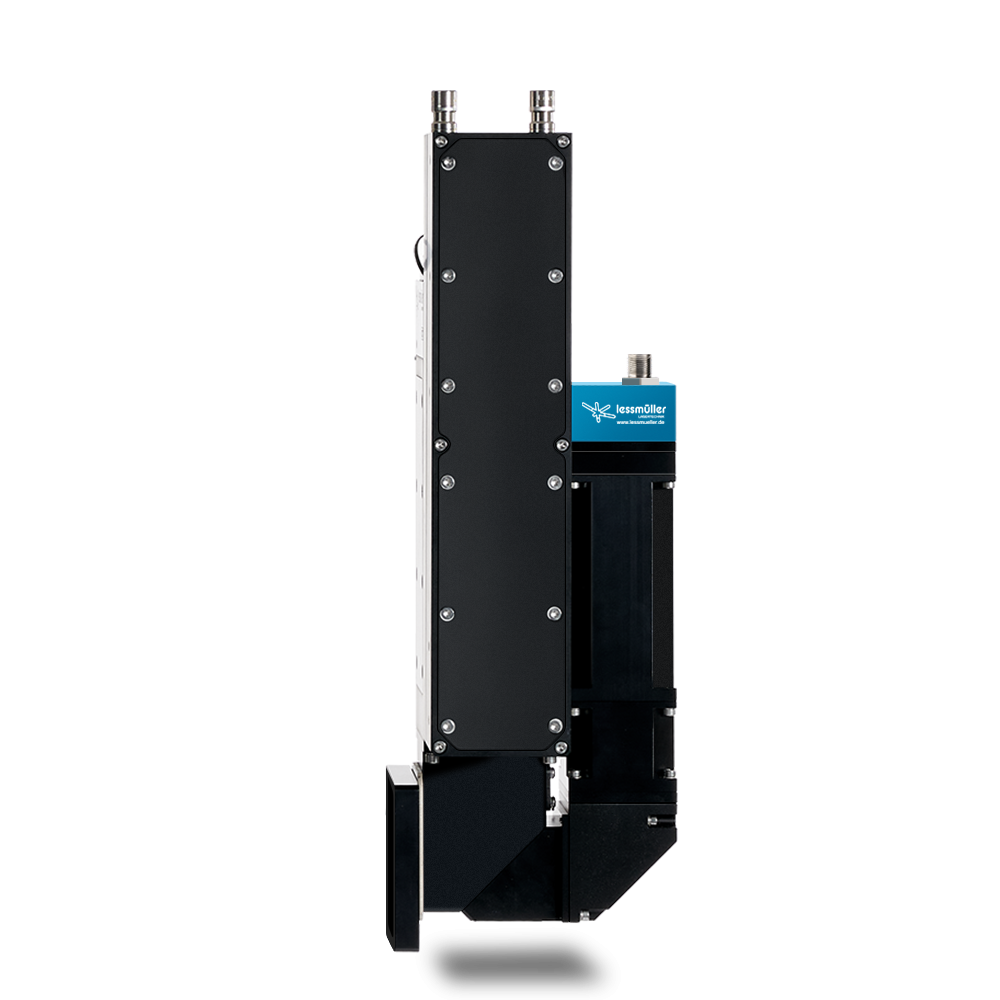

Lessmüller Lasertechnik offers suitable sensors for all fields of application:

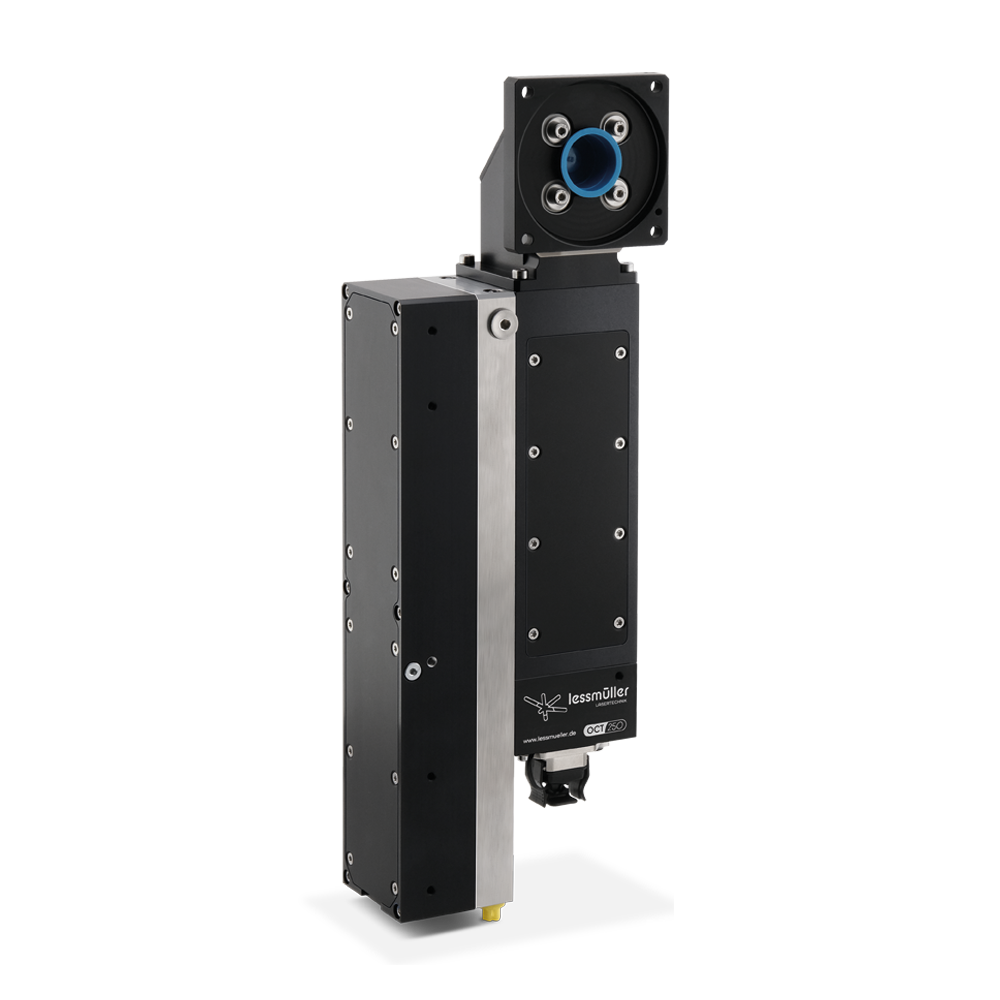

- OCT – Optical Coherence Tomography

- WELDEYE – Camera surveillance with external lighting

OCT for high quality laser welding

OCT is an innovative technology introduced in the automotive manufacturing process for the industrial monitoring of laser processes, as it can be used contactless, has a high dynamic range and has a resolution of a few micrometers and is insensitive to all optical disturbances (processing laser light or other rays). Thanks to three-dimensional images, OCT offers height-based image analysis on-the-fly. Saving time and materials is an attractive feature for car manufacturers. In this sense, OCT is a precise tool for fast, adaptive, direct and quantitative process monitoring during the laser welding of body, transmission and powertrain in real time. Certain quality improvements can be achieved with OCT.

The high lateral and axial resolution of OCT enables the detection of the open pores at the weld seam during the welding of powertrain (powertrain) components.

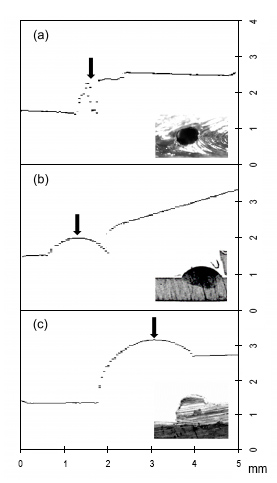

OCT visualization of a weld seam topography

Image: OCT images with corresponding photos of the weld defects (denoted by arrows) on the fillet welds: (a) a pore with the size of 0.2 mm at the weld on galvanized steel sheets; (b) Welding off the butt joint on the aluminum bottom plate; (c) Welding off the butt joint on the galvanized steel top plate. Thanks to the OCT measurements, an immediate automated error correction could be initiated.

The OCT technology offers tailor-made solutions for µm-accurate real-time process monitoring and quality assurance in laser welding. OCT a promising instrument for industrial weld depth measurements in laser welding.

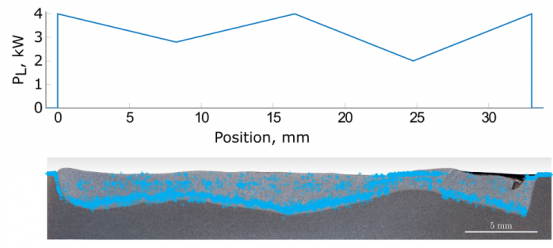

Image: Laser power variation (upper diagram) and simultaneous OCT measurement of the penetration depth (blue crosses in the image below) via the light microscopy image of the longitudinal section.

The destructive sampling can therefore be reduced. With the usual welding parameters in the automotive industry, OCT satisfactory results for the post and in-process Control.

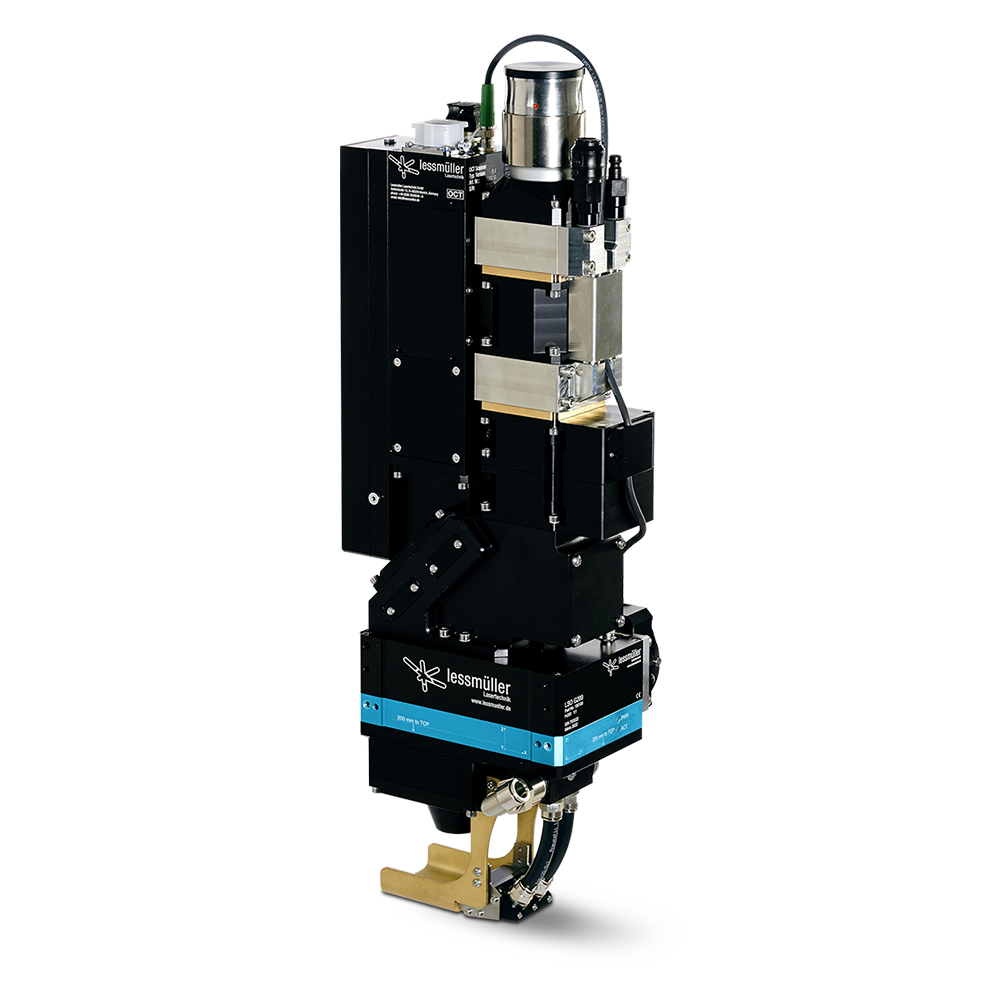

Automated, regulated quality assurance with WELDEYE

Effective laser processing requires precise automated online process monitoring. With WELDEYE, the system takes live images during the active welding process, illuminated by the laser optics using high-power external light, in order to close the weld pool and the reflections of the cooled weld seam measured and thus visualize the continuous laser welding progress. These images are used, among other things, to map the environment of the welding process. The alternating recording of illuminated and non-illuminated images enables the evaluation of the process light and the cooled weld seam. The determined values for the pass/fail decision are transmitted to the robot control software via the direct and fast communication interface.

WELDEYE is an established camera technology that is widely used to ensure optimal quality welds. WELDEYE can either classify the measured values based on absolute limit values or learn suitable limit values from reference welds.

The WELDEYE system is used for synchronous recording and evaluation of image data and process parameters using camera and extraneous light-based real-time process visualization.

.

Product solutions for laserwelding car body construction

You don’t find your business here? No problem…

Car body construction

Car body construction