White goods

White goodsPROCESS MONITORING WHITE GOODS PRODUCTION

More safety in the welding process for more production

In addition to automotive and medical applications, laser processing is widely used as a time- and cost-efficient process for welding commercial components in so-called white goods, i.e. household appliances such as washing machines, tumble dryers, refrigerators, freezers and dishwashers: from welding, control elements or electromechanical components to joining frame elements and stainless steel housings, etc.

The number of white goods (household appliances) produced and sold annually is continuously increasing from year to year. Lessmüller Lasertechnik supports the manufacturing industry in keeping pace with consumer demand for household appliances and achieving more efficient productivity, for example, through the use of sensor technolgy for laser welding robots. To increase output, process monitoring of automated welding equipment is required: components must be continuously measured and checked online at the individual steps in the production line, and welding parameters must be changed online as needed.

For the production of high-quality white goods products such as refrigerators, washing machines, ovens, dishwashers, the welding process must be monitored by suitable sensor systems during the automated laser process. Sensor technology for laser welding from Lessmüller Lasertechnik GmbH ensure reliable weld seams and optimal, high-precision joining joints, which are necessary to create defect-free products. Parameters can be constantly checked so that deviations can be detected and appropriate measures taken, which is made possible by intelligent software-based process monitoring functions.

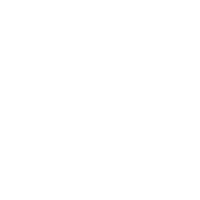

Example of laser welding of large electrical appliances for domestic use. High-quality weld (picture above) on a washing machine drum welded at high speed over a large working area on a large as well as thin stainless steel plate. OCT measurements (below) of the joint (left) are used for precise beam positioning and those of the weld bead (right) for quality assessment.

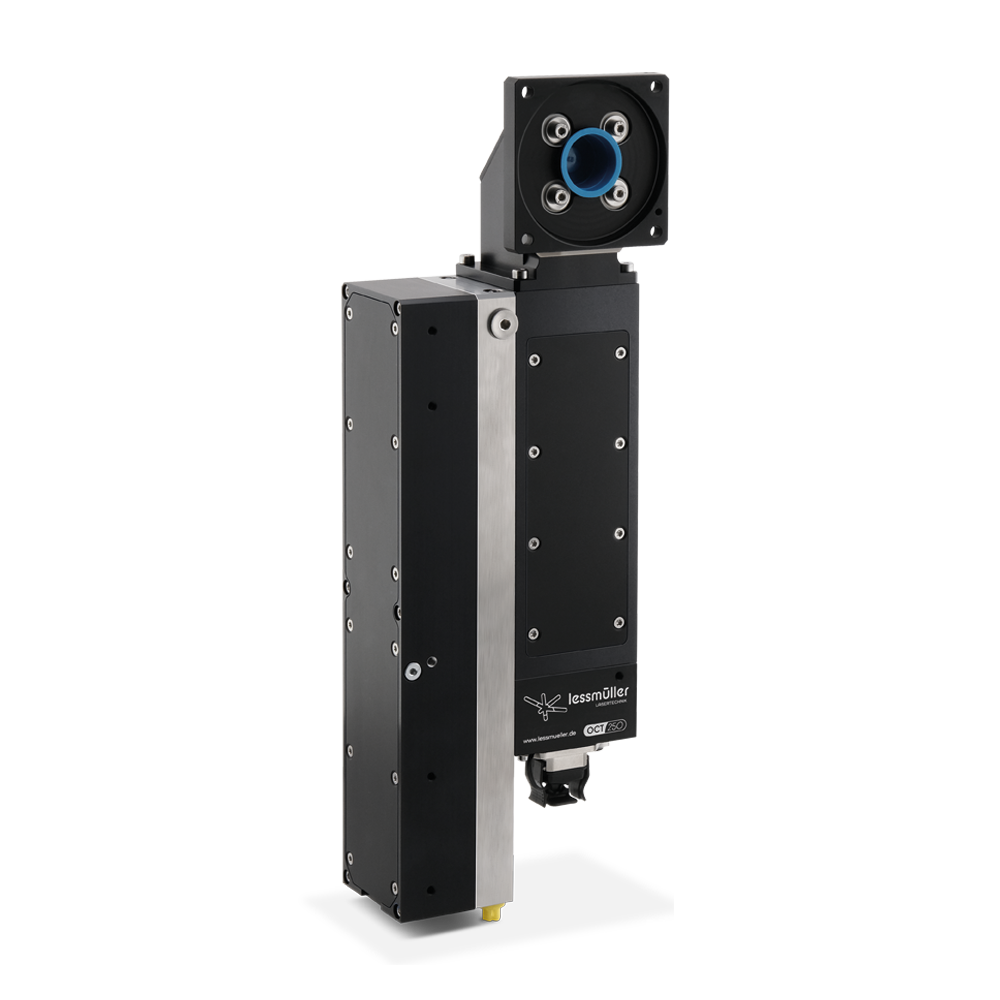

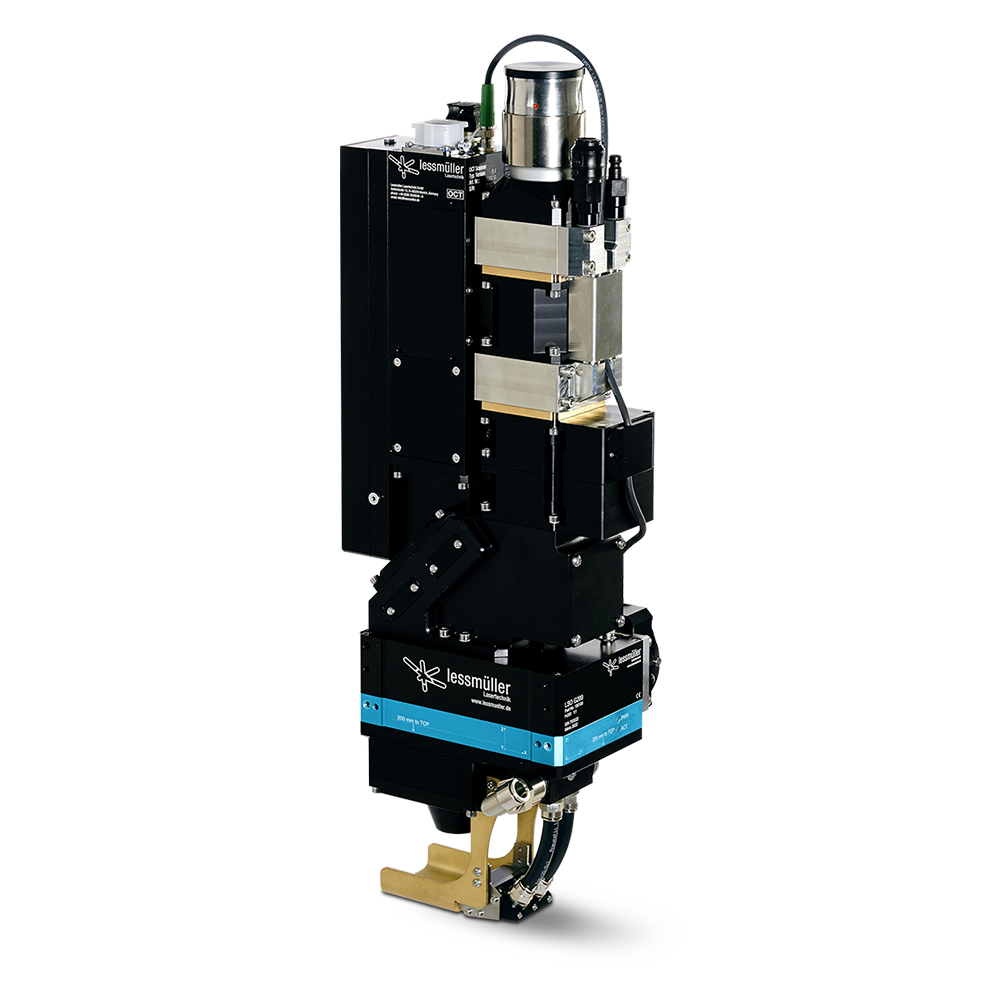

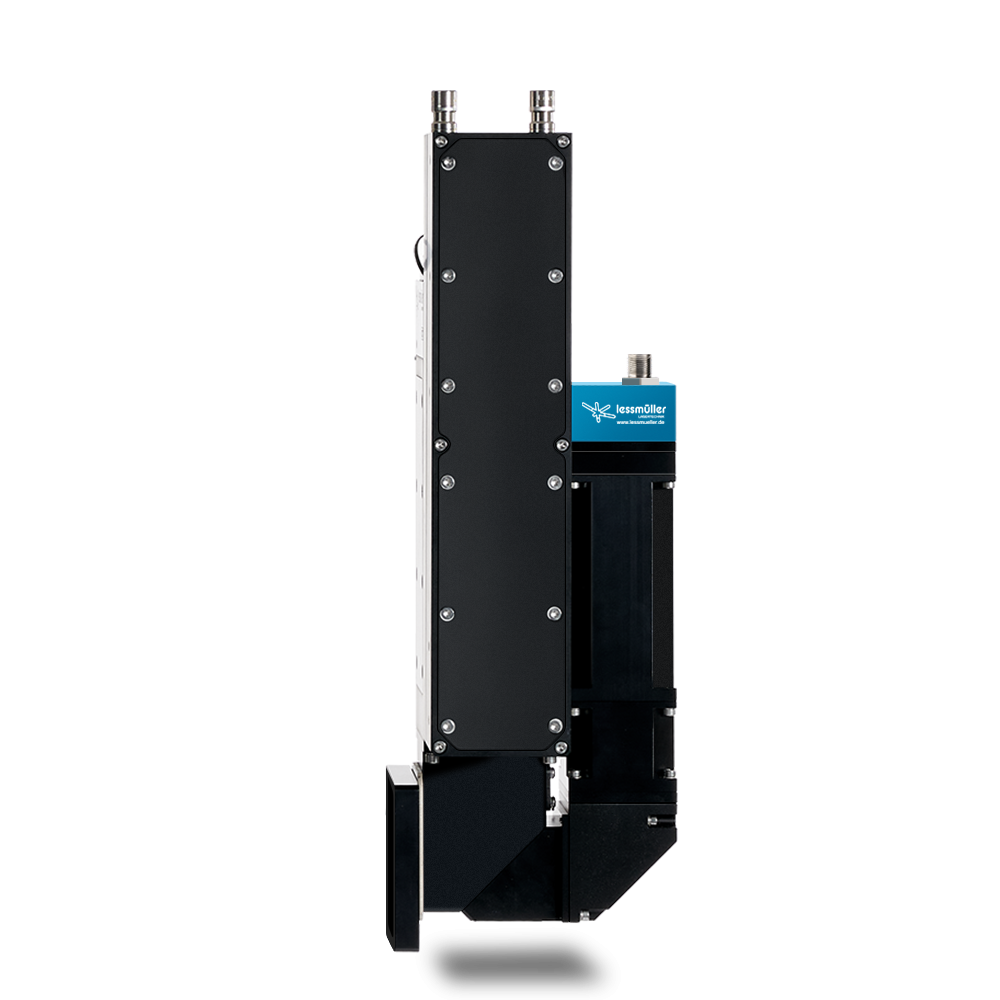

Installed on various remote and fixed welding optics, Lessmüller Lasertechnik sensor technology for laser welding demonstrate real-time control capability with high precision and over a wide dynamic range. They provide seam tracking (including beam positioning), seam depth measurement, seam quality control with OCT, process monitoring with WELDCHECK, seam inspection with WELDEYE, and enable faster laser processes and streamlined production services for laser welding of white goods. These special solutions from Lessmüller Lasertechnik make laser welding ideal for applications where accuracy, cleanliness and durability are critical to success.

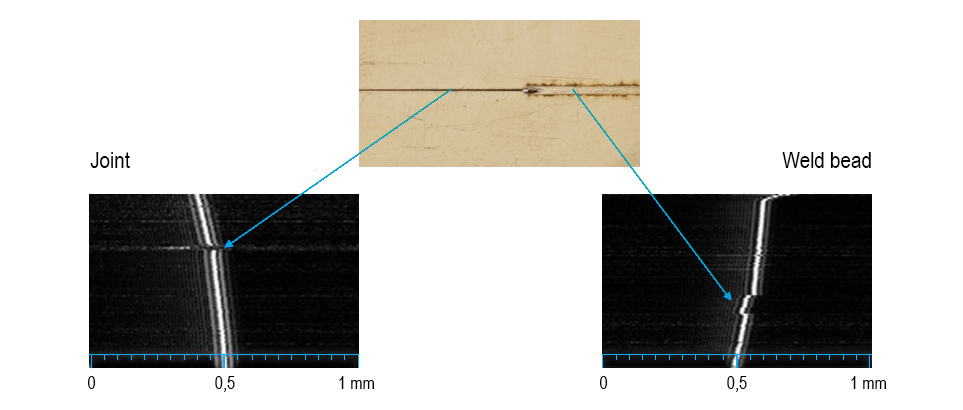

OCT image during axial positioning relative to the reference surface. The distance between the reference surface and the top of the valve was measured with an accuracy of 12 µm. A high axial resolution can be advantageous in some applications, e.g. welding of valves, where an exact height position in the focus of the laser beam is required.

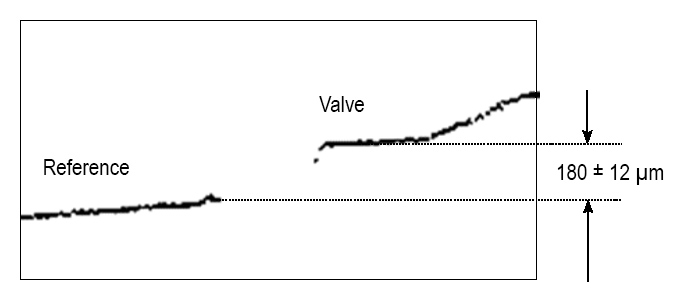

OCT application demonstrated on pressure sensor. Beam positioning for spot welding on small white goods components becomes a simple task when the exact position of the joint is determined by Lessmüller OCT.

.

Product solutions – sensor technology for laser welding

Sensor technology for laser welding

Sensor technology for laser welding

Lessmüller Lasertechniks Sensor technology for laser welding made in Germany for high quality laser welding.

You don’t find your business here? No problem…