WELDEYE

WELDEYE

Product features WELDEYE

WELDEYE

Laser welding process monitoring and visualization

Lessmüller Lasertechnik’s WELDEYE has set standards in quality assurance with more than 500 systems installed worldwide.

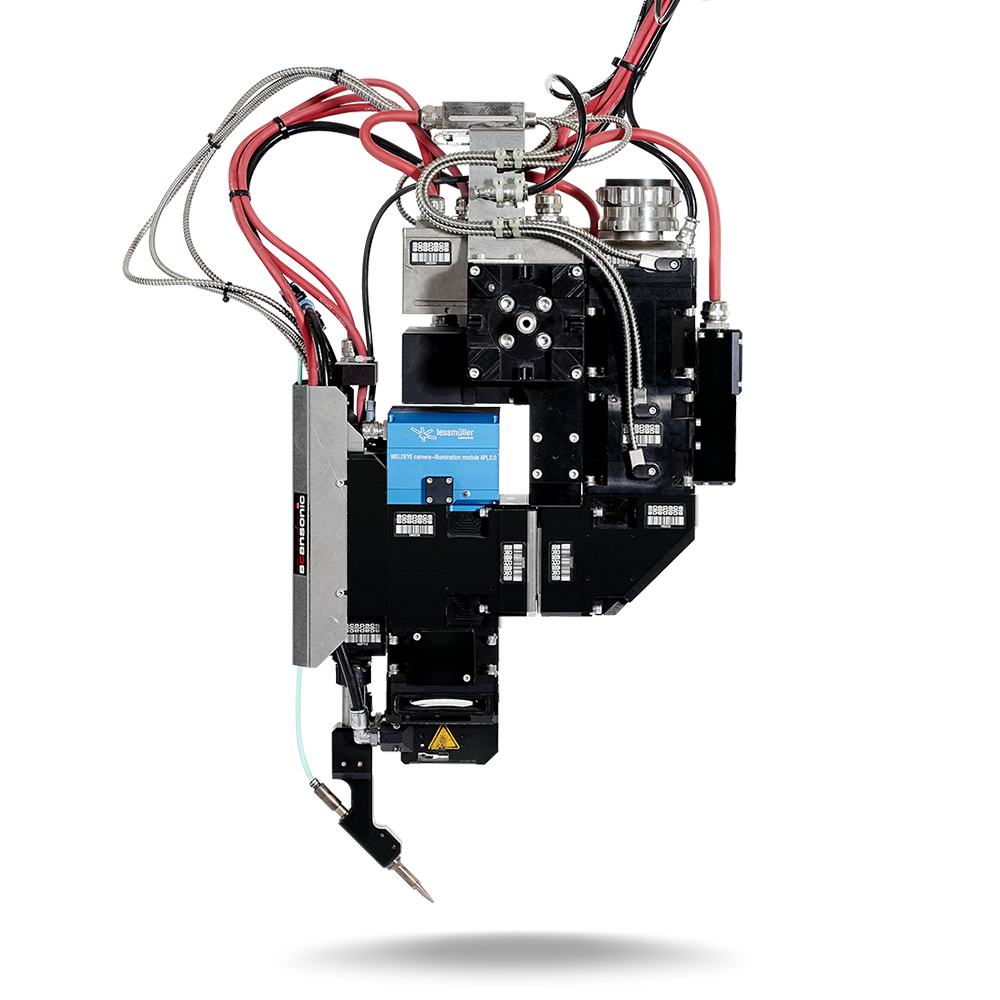

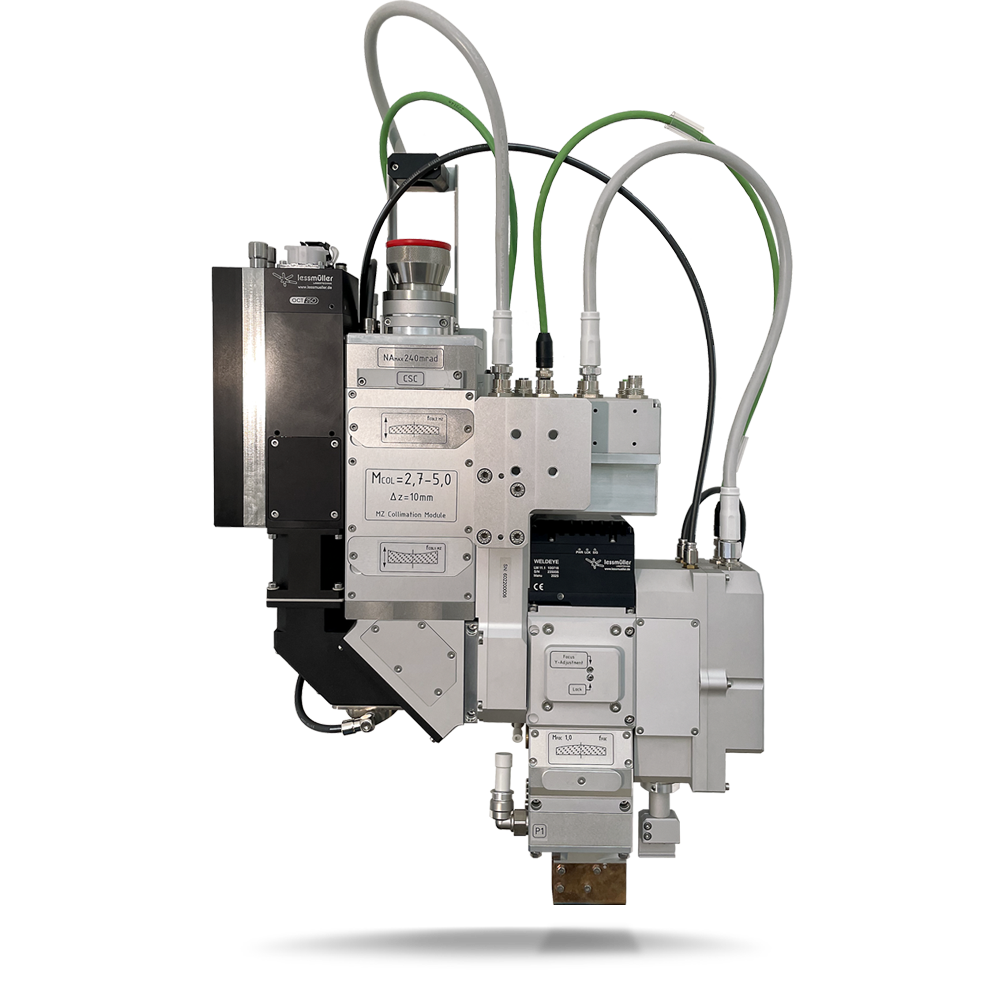

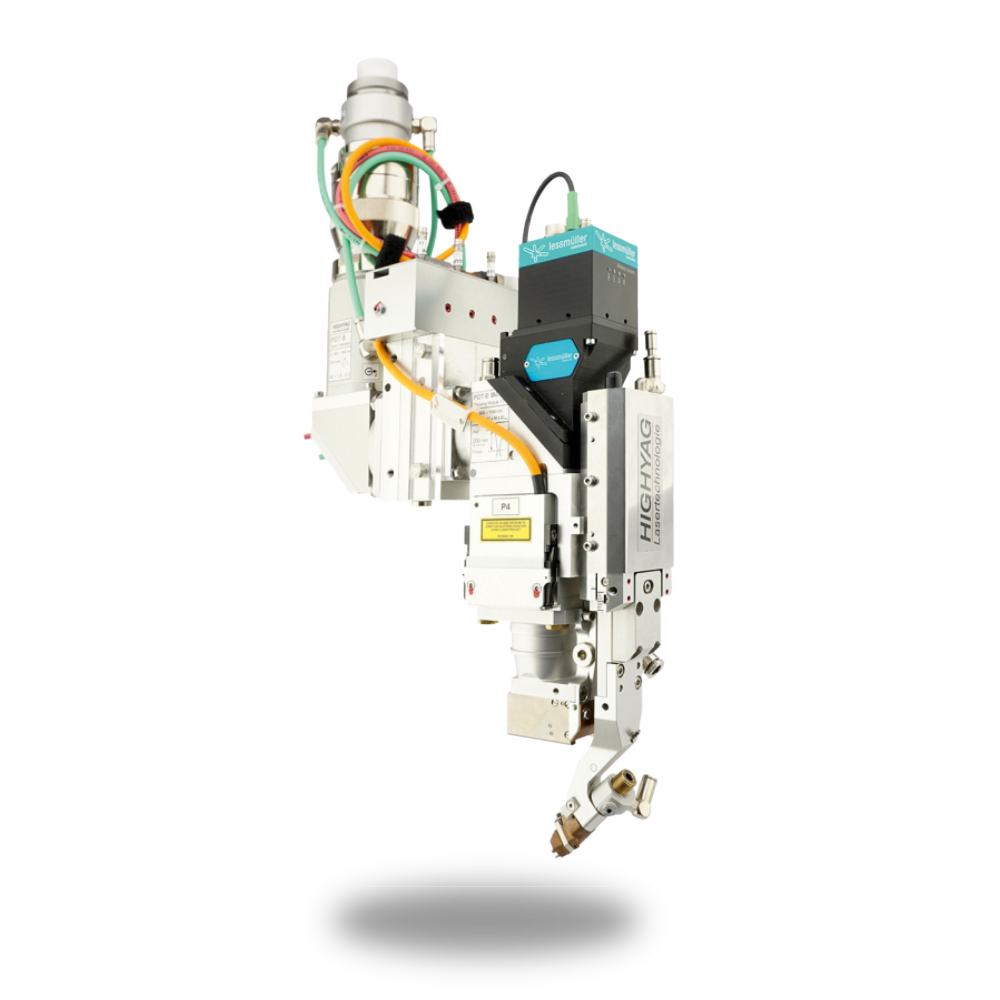

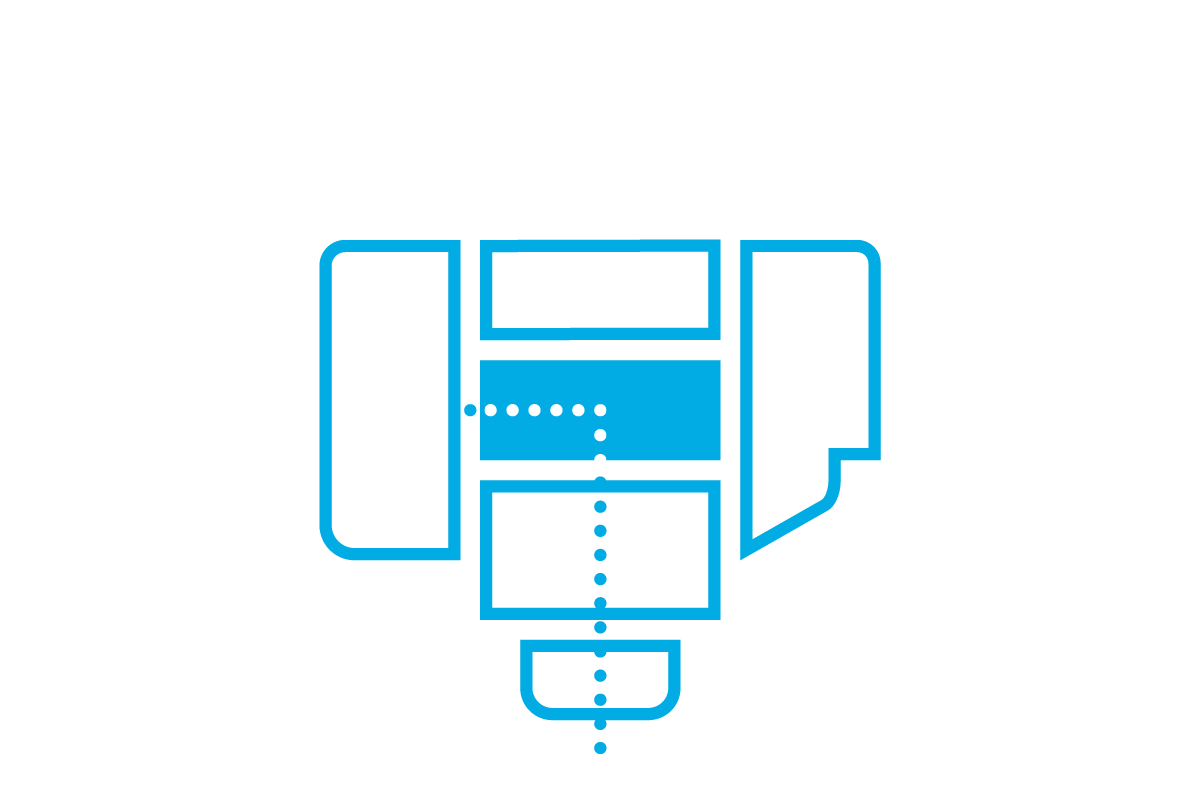

The module-based WELDEYE system visualizes the welding process (laser welding process monitoring), enables online seam tracking, ensures quality in laser welding processes and is universally adaptable for many welding optics.

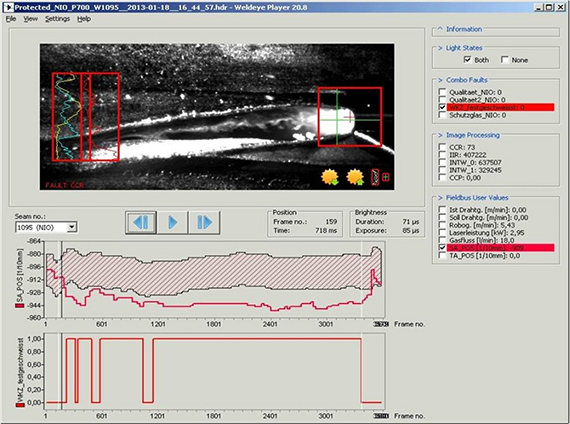

The synchronous recording and evaluation of image data with process parameters and control data of the system opens up completely new possibilities in laser welding process monitoring. Whether welding wire defects or seam interruptions caused by dirt – WELDEYE sees everything:

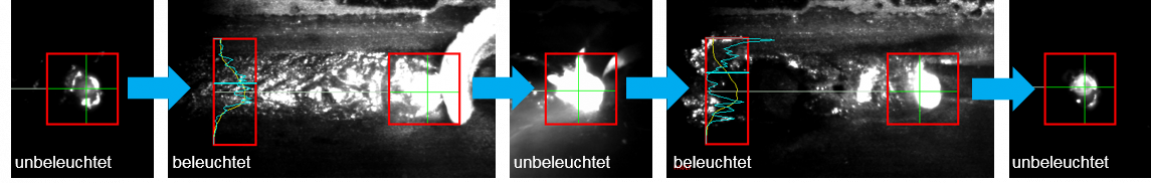

The system consists of a high-speed camera with optical filter and a powerful illumination source. During the active welding process, the process light radiation is “blanked out” by the filter, sequential images are taken with and without external illumination and evaluated in real time.

Thus, the position of the weld joint as well as the weld pool and the reflections of the cooled weld seam are continuously measured, e.g. for gap measurement.

The high level of information provided by these camera images enables automatic evaluations to be programmed. Quality algorithms proven in series production monitor the welding position, process and seam, correct positional errors and report welding defects – in real time.

Successive exposures with alternating illumination for defect analysis. Here: detection of holes in the weld seam caused by dirt.

All welds are continuously recorded, automatically analyzed and stored. The entire process is monitored in real time and compared with data from reference runs. Deviations in the current welding process from these definable references are reliably reported by the system to the higher-level plant control system.

WELDEYE is designed according to the modular principle. The user can implement the entire system or individual functions.

- Lighting module LM6

- Camera module CM 3.0

- Camera module CM 3.0 + Lighting module LM7

- Lighting module LM5

- Fibre laser collimator with ball head holder

- Lighting module LM4

Advantages with WELDEYE

- Real-time weld guidance, process visualization, monitoring and quality assurance for laser welding process monitoring and brazing

Real-time recording of LIVE camera images of the welding process and image analysis

Synchronous recording and evaluation of image data and process parameters (e.g. feed rate)

Automatic defect detection and auto-correction to reduce downtime and scrap production, inspection costs and rework rate

Integration with many common laser welding optics

Compact and lightweight design, low interference contour

Communication via standard fieldbuses

Rugged industrial design: dust-tight construction (IP-64) with robot-towable cable and interfaces

APPLICATIONS

Here, our WELDEYE solutions have already proven their worth …

Product Advise

.

Product solutions

Downloads

WELDEYE for scanner and fixed optics

You don’t find your business here? No problem…

WELDEYE

WELDEYE