Welding monitoring

WELDING MONITORING SYSTEM

Monitoring and documentation – individually adapted to your welding processes with the laser welding monitoring system

The use of automated, robot-guided laser welding systems in serial production requires that humans are shielded from the manufacturing process for reasons of laser protection. We offer the following Laser weld monitoring system for this purpose.

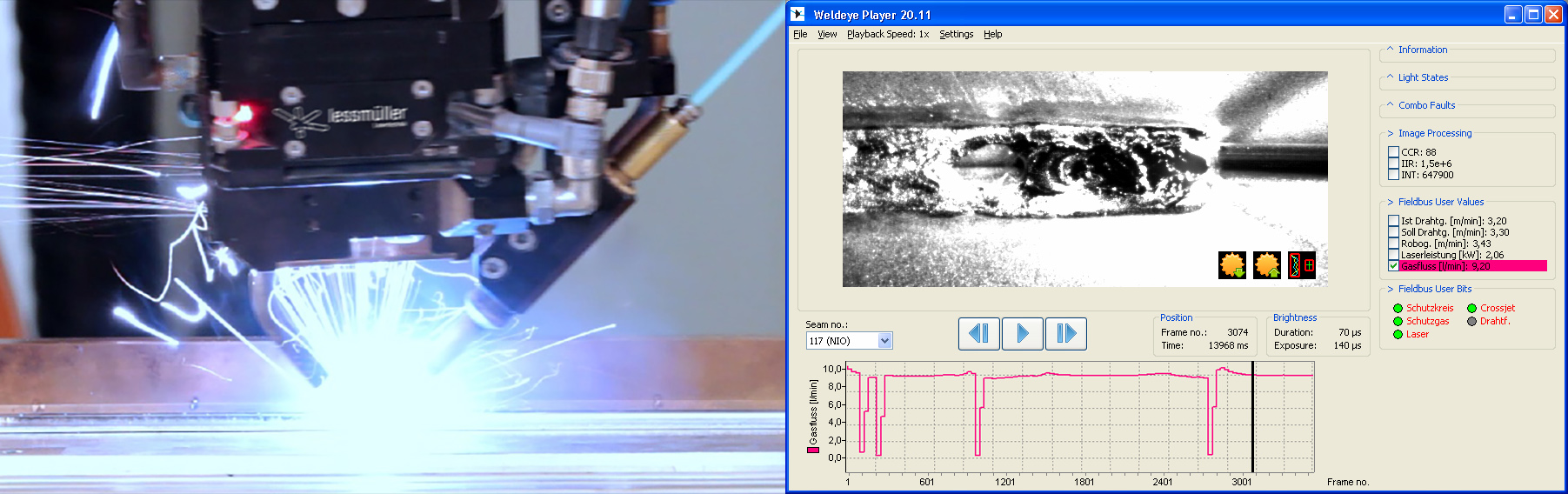

WELDEYE

The WELDEYE is based on a camera system with external illumination, which can be adapted to many common laser welding optics. This system shows a live image of the welding process and brings the user virtually with the eye to the weld seam:

- Combination of intelligent control, camera and lighting technology

- Synchronous recording and evaluation of image data and process parameters of the system (e.g. wire feed speed, shielding gas volume, laser power)

- Avoidance of unnecessary material and time costs through early defect detection

- Analysis of faults with the aid of video recordings and the current parameters at the time in question

Client software interface

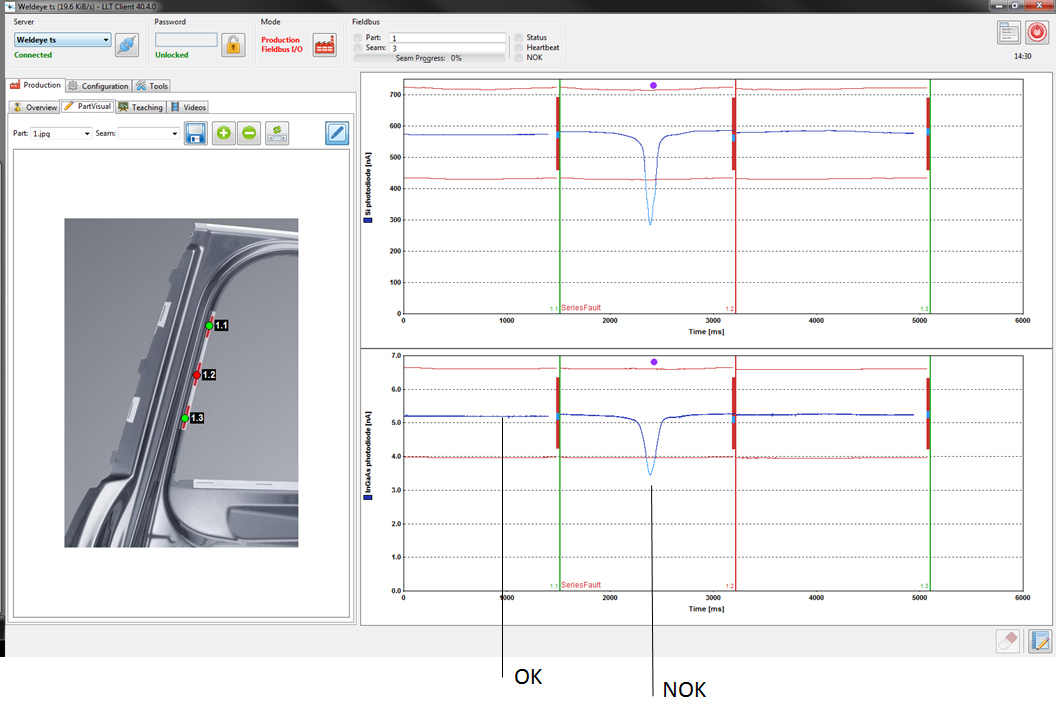

WELDCHECK

The diode-based WELDCHECK system is used to monitor the process light during the welding process. Here, two photodiodes, one in the visible and one in the near infrared range, compare the process glow with a reference weld specified by the user and rated as good.

- Detection of deviations in welding results and resulting trends

- Easy integration to all processing optics with camera connection

- Compact design – evaluation unit (EVA) fits on DIN rails in typical supply cabinets and control cabinets.

- Effective and cost-efficient system

- Easy determination of production scrap

Screenshot shows defect detection with WELDCHECK

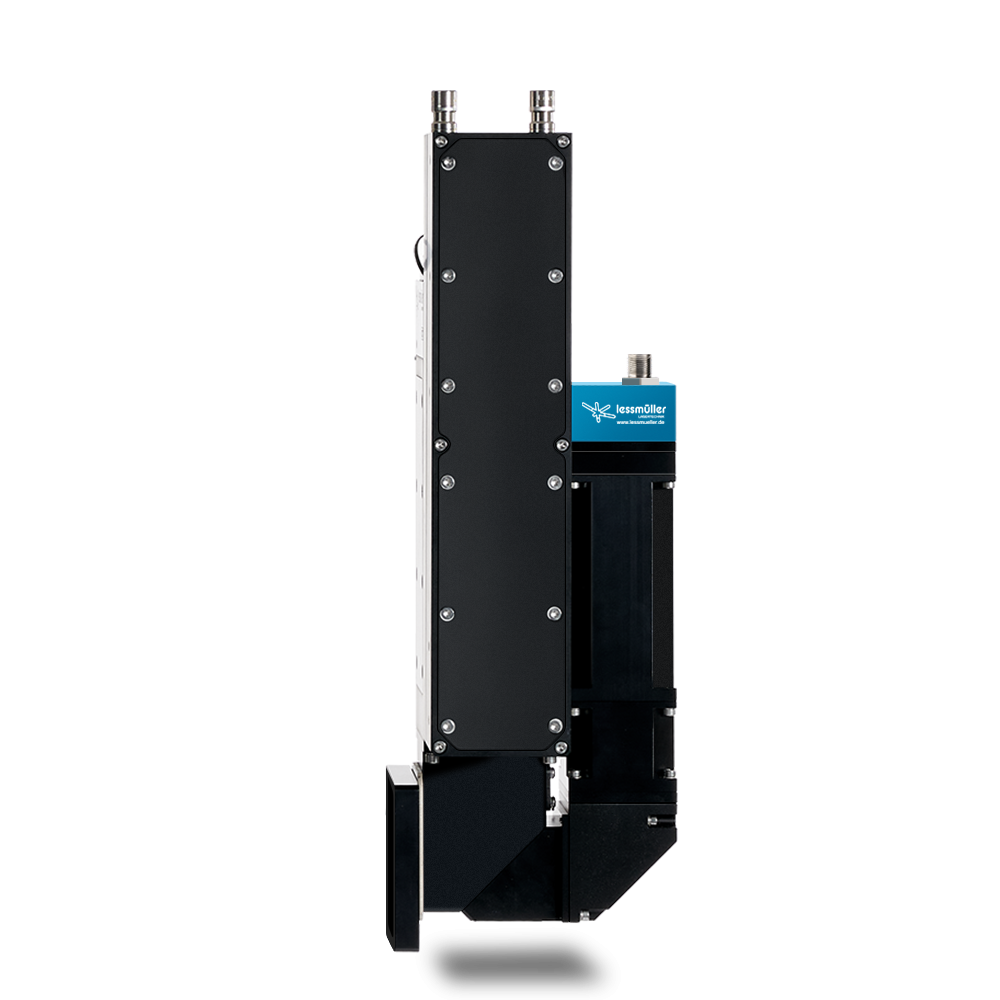

In the case of extended requirements for weld monitoring, for example for measuring the micrometer-accurate welding penetration depth during the welding process, the OCT system from Lessmüller Lasertechnik, which is based on optical coherence technology, is also an option. In addition to weld monitoring, this system can also take on further tasks in all process monitoring areas (pre-, in- and post-process).

At home in many industries

.

Product solutions – Laser welding monitoring system

You don’t find your business here? No problem…