Powertrain

Powertrain

WELDING MONITORING SYSTEM FOR POWERTRAIN

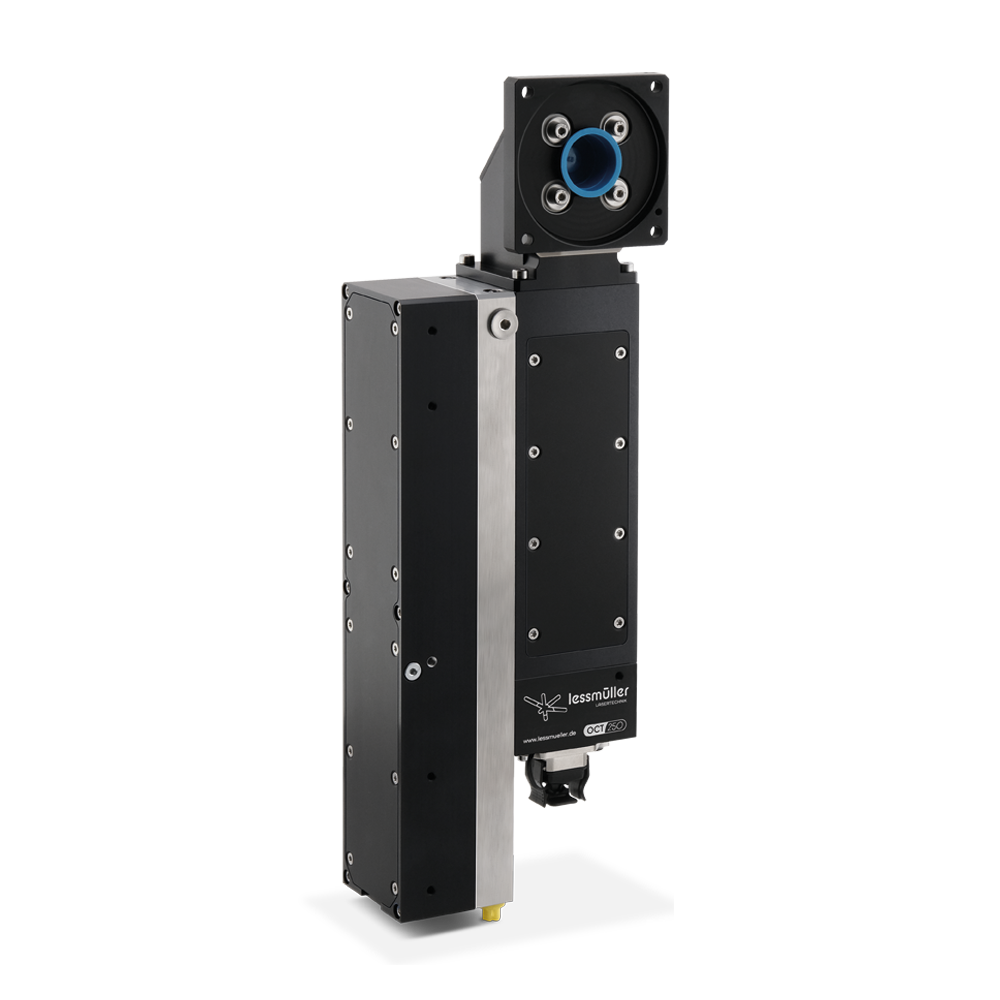

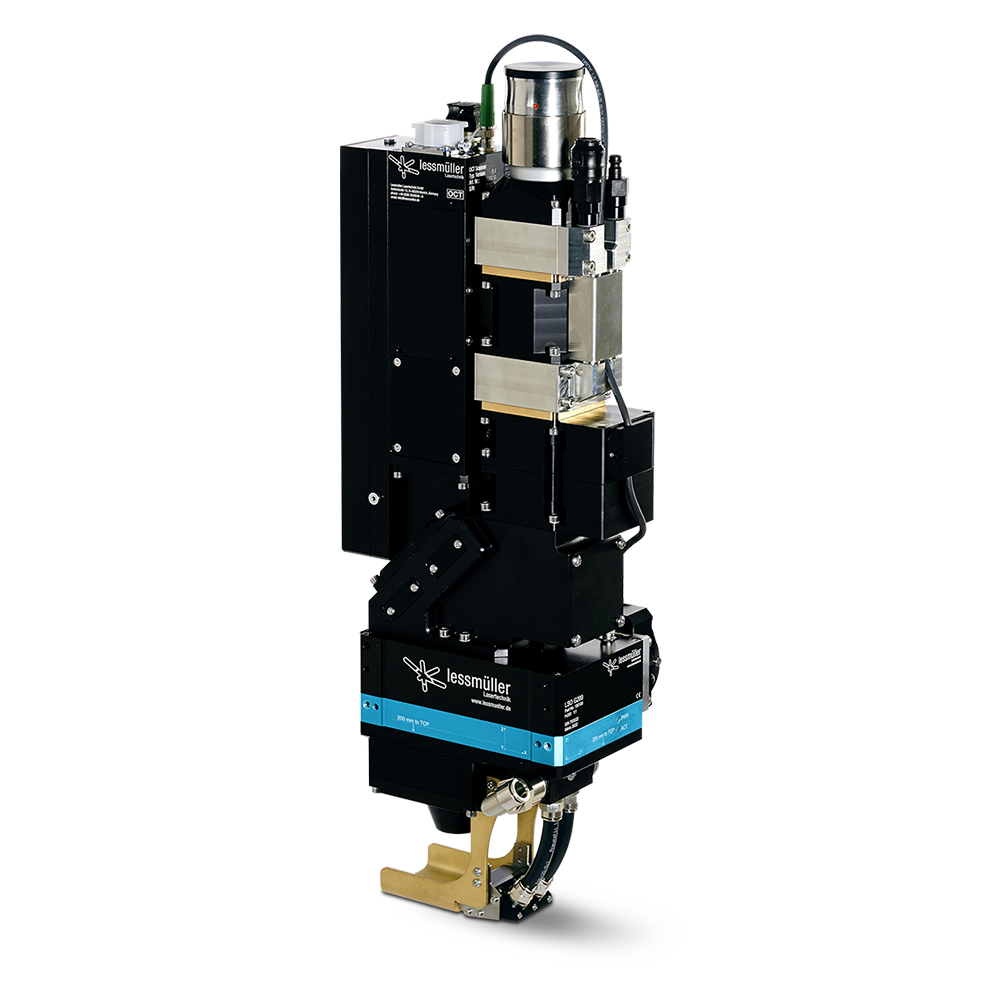

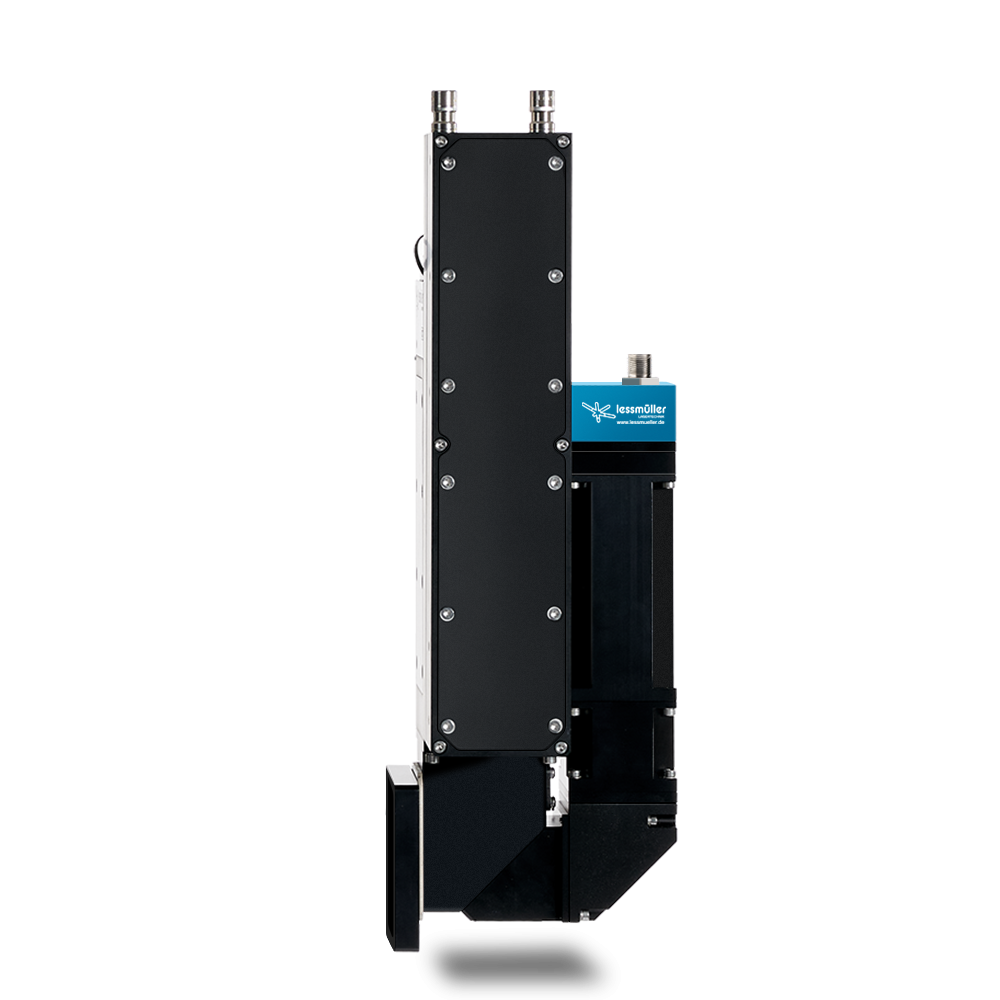

OCT sensor technology and camera monitoring

Various techniques have found industrial application in automotive series production to monitor laser processing on site. Among them:

- OCT – Optical Coherence Tomography

- WELDEYE – Camera monitoring with external illumination

Laser processing heads equipped with OCT (optical coherence tomography) offer a number of advantages that serve to increase productivity and reduce production costs for the automotive industry. These include consistency, precision, real-time performance, high flexibility and capture rate, and insensitivity to the welding environment.

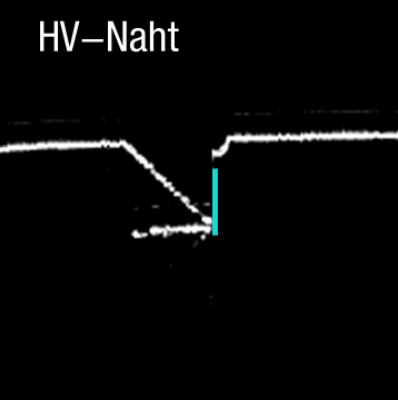

The high precision of the OCT tool can achieve detection of weld butt joints with exceptionally high aspect ratio (flange joint) or small aspect ratio (drives V-seam).

Another example is the OCT application seam tracking when welding a drive wheel. The vertical cyan line shows the automatically detected seam position.

Successful experience of operation in series production of vehicles makes OCT suitable as a sensor technology for today’s laser processing trends. Its application contributes to technological progress in the automotive industry and to meeting customer requirements.

OCT is a precise tool for fast, adaptive, direct and quantitative process monitoring during laser welding of powertrain components in real time.

The high lateral and axial resolution of OCT enables the detection of the open pores on the weld seam during the welding of the car drive wheels.

For more information on OCT and WELDEYE from Lessmüller Lasertechnik, see also

.

Product solutions – welding monitoring system

You don’t find your business here? No problem…

Powertrain

Powertrain