Battery construction

Battery constructionBATTERY CONSTRUCTION LASER WELDING BATTERY CELLS

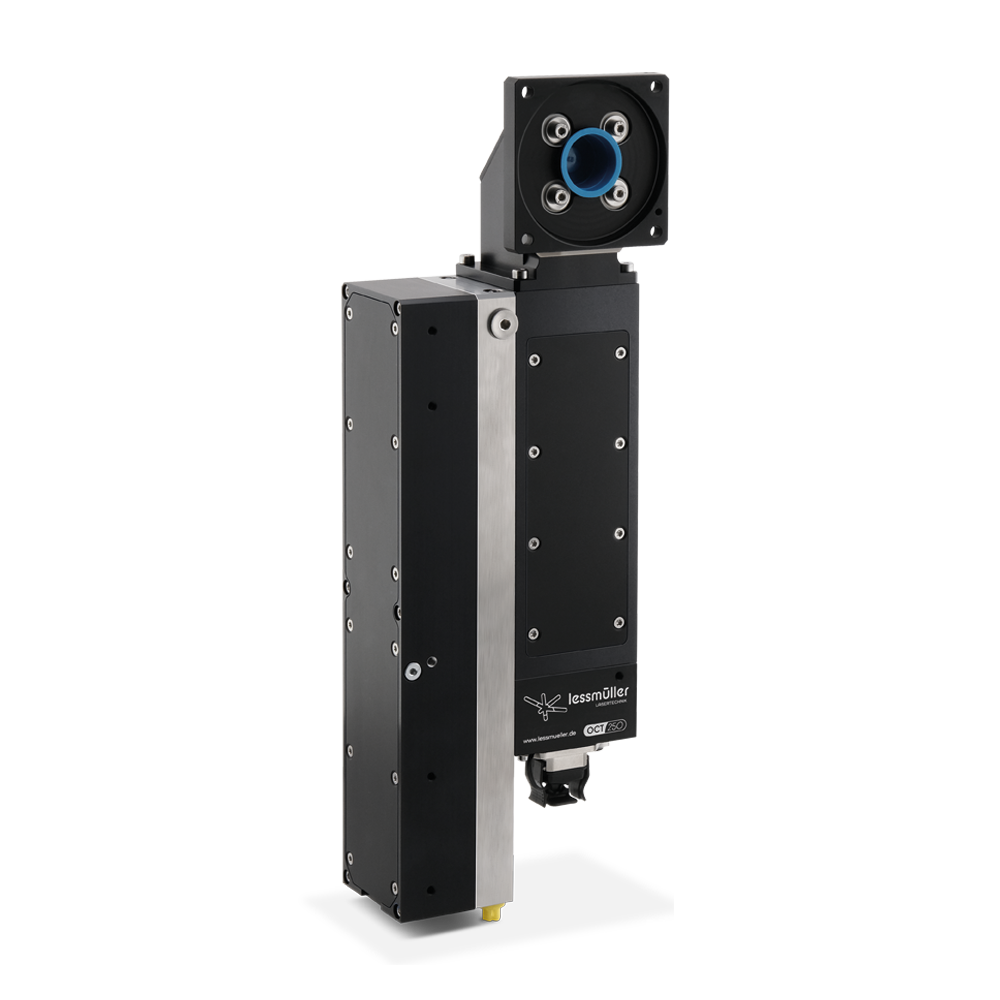

Maximum quality assurance with OCT sensor technology

Without laser welding, the implementation of electromobility on a large scale would be unthinkable! The laser finds applications in the construction of battery cells, in the joining of cells into modules, in the installation of modules in packages and also in the drive itself as well as in the construction of electric motors and power electronics.

And no laser process without sensors! This is why optical coherence tomography (OCT) technology has a special and groundbreaking key function. It now plays an essential role in the production of electric vehicles and the welding of batteries, not least due to the ultra-high accuracy in the seam tracking of the process laser beam.

The high resolution of OCT systems makes it possible to investigate surface porosity during laser welding of battery components in electric vehicles. For safety reasons in particular, battery welding must produce a hermetic joint with high strength and very low porosity that prevents the ingress of moisture and corrosion.

By acquiring OCT data, the entire weld topography can be measured and stored for subsequent process observations. Accurate quantitative evaluation of weld topography with OCT enables the identification of defects such as open pores for quality control.

The high accuracy of this quality control tool can be seen on these two videos of laser welding battery cells:

OCT example of weld quality assessment (post-process). The red dot on the video is the leading pilot laser scanning the finished round weld. The trailing cross lines correspond to the scan scanning of the OCT. (Scan result in the next video.)

Scan result: 3D seam topography of the circumferential weld with a weld defect (pore).

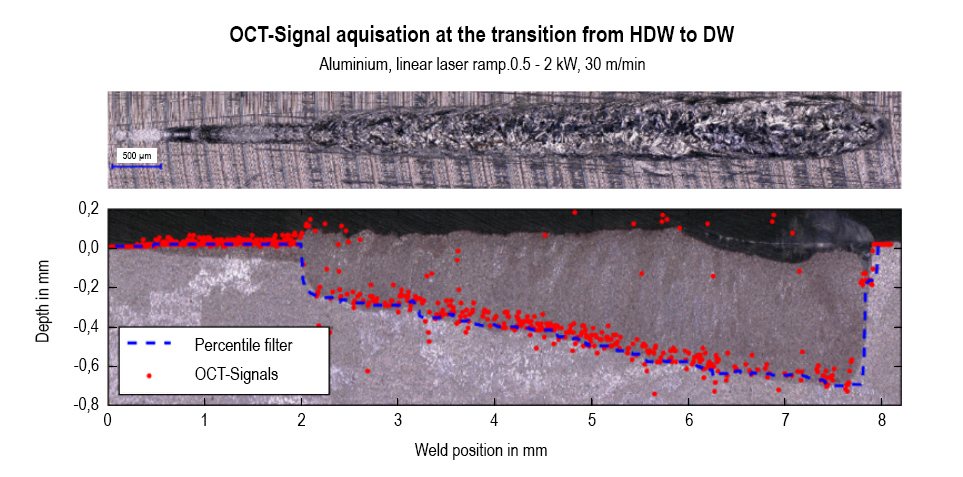

Another application in the field of electromobility is the welding of busbars in various material combinations and geometries. The weld must be deep enough to ensure a sufficient connection cross-section for minimum electrical resistance and maximum strength without penetrating through the busbar into the highly sensitive battery cell. The weld depth measurement option makes it possible to accurately determine and control the weld penetration depth at any time and eliminate the need for costly and time-consuming longitudinal grinding for quality assurance.

OCT measurement of the weld penetration depth and the real longitudinal grinding of the same seam area.

All in all, laser welding systems equipped with OCT sensor technology offer the operator a high degree of flexibility and, in particular, safe, constantly monitored process reliability, which sustainably increases the operator’s own product quality.

You don’t find your business here? No problem…