LASER WELDING SEAM TRACKING / GUIDANCE

Precise seam search and laser welding seam tracking – individually adapted to your welding processes

Precise positioning of the processing laser creates the prerequisite for optimum welding results. At the same time, the use of remote processes and welding-on-the-fly in industrial series production makes a decisive contribution to avoiding unproductive repositioning phases.

Lessmüller Lasertechnik offers you various seam tracking systems that can be used in combination with laser welding seam tracking optics from a wide range of manufacturers and ensure high-quality seams in efficient production. These automated and highly dynamic systems determine and control the optimal welding position while compensating for component tolerances or changes in the welding plane:

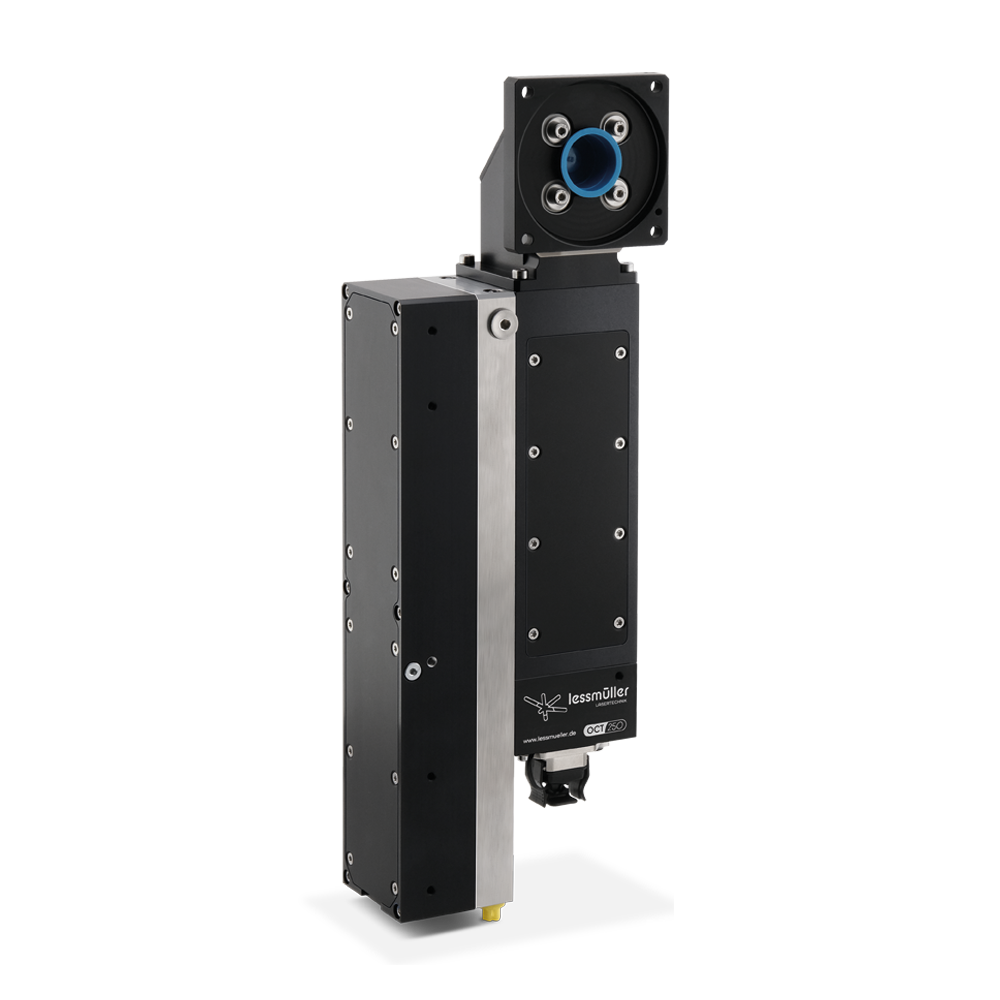

- The OCT (Optical Coherence Tomography) system provides highly accurate, non-contact surface measurement of all common joining points as well as dynamic position correction of the processing laser beam during the welding process in real time. Hairpins can also be precisely measured with this system in terms of geometry and their position relative to each other in order to achieve the optimum welding position. In principle, OCT is compatible with all common welding optics.

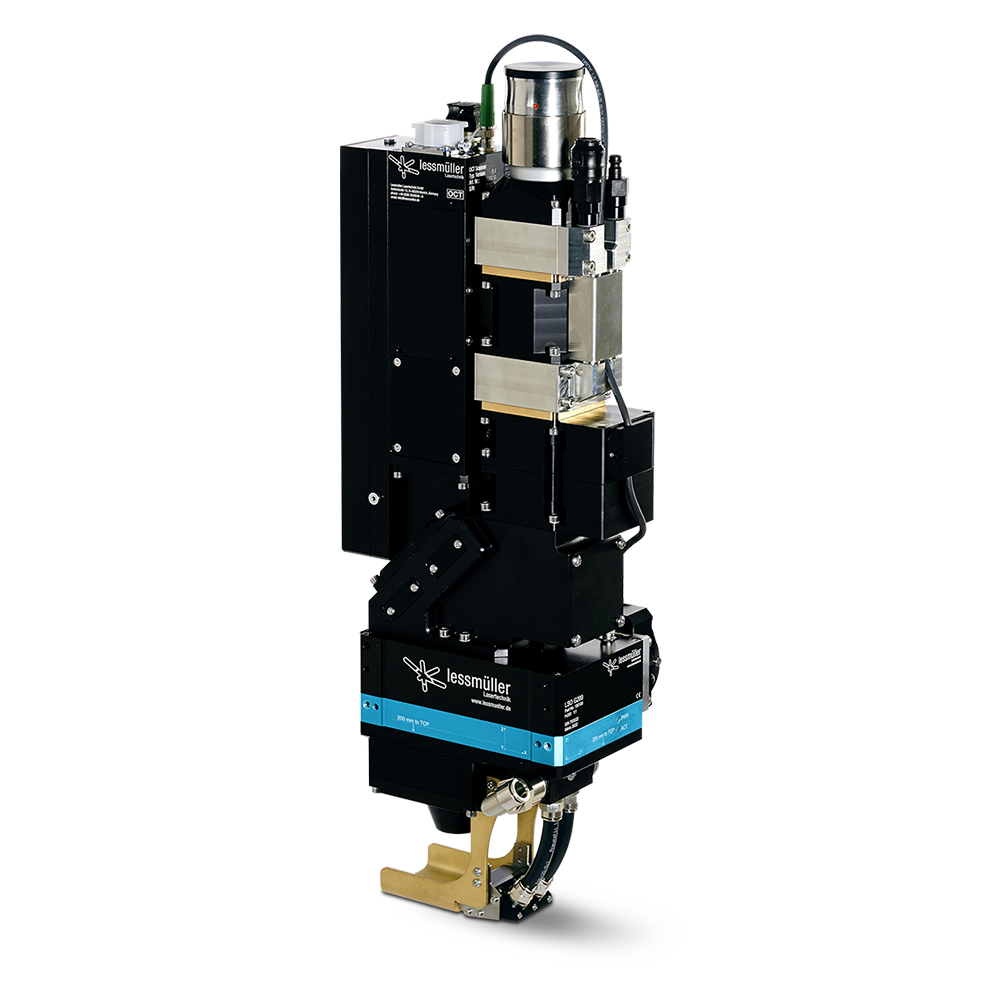

- The LSO system (Lens Shifting Optics) is an in-house processing optics for joints with small deviations of up to 2.5 mm. LSO closes the gap between fixed optics and process optics with scanner technology. Here, LSO and OCT form an ideal system unit that guarantees highly dynamic correction of the welding position and the focal position during the welding process and reliably ensures an optimum welding result. For the user and integrator, this unit presents itself as a black box that is easy to integrate.

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our

Datenschutz.

- The WELDEYE system with camera and extraneous light based seam tracking and real-time process visualization is used hundreds of times in welding and brazing with filler wire and has proven itself for over 10 years.

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our

Datenschutz.

All measurement and evaluation data of these systems can be stored in each case and thus enable complete traceability.

At home in many industries

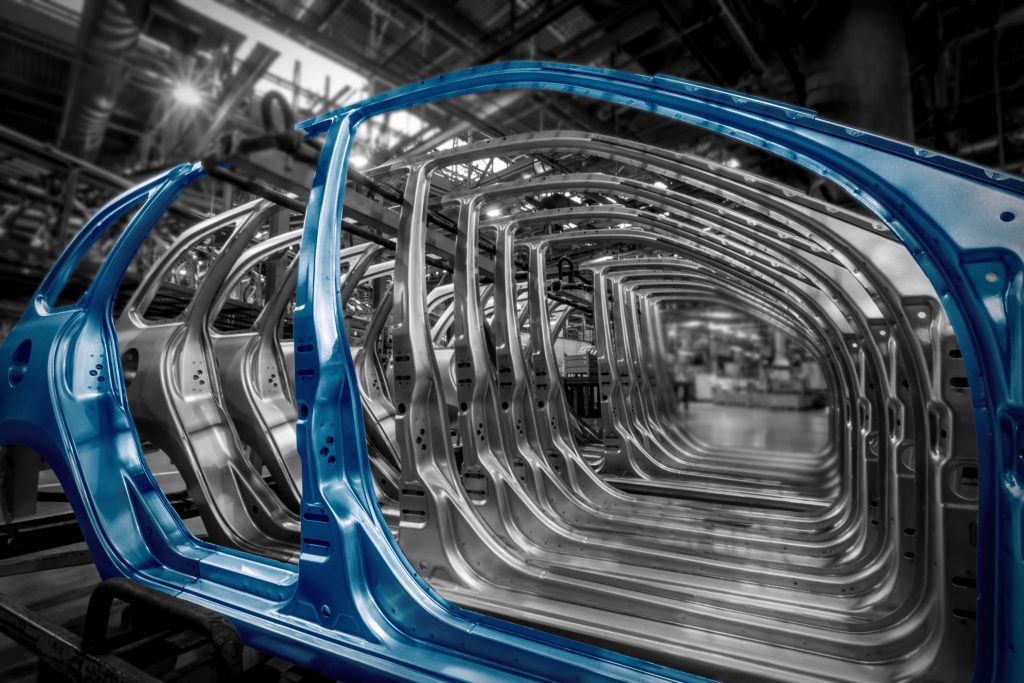

Process monitoring car body construction

The automotive industry is the technological trendsetter in the manufacturing industry. Fully automated, high-speed laser welding of various components in unattended operation without time-consuming setup is the rule not the exception.

Laser welding systems must operate independently, especially at high volumes. Despite the high welding speed, the laser beam must precisely hit the weld joint … >> read more

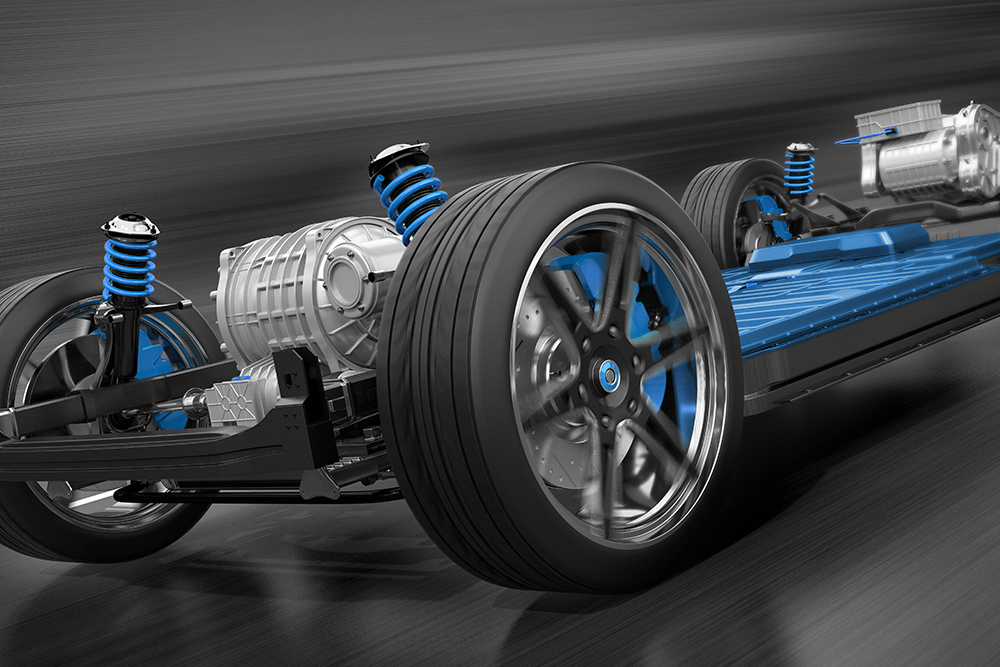

Process monitoring powertrain

Various techniques have found industrial application in automotive series production to observe laser processing in the field. Among them:

OCT – Optical Coherence Tomography

WELDEYE – Camera monitoring with ext. illumination

Laser processing heads equipped with OCT (optical coherence tomography) offer a … >> read more

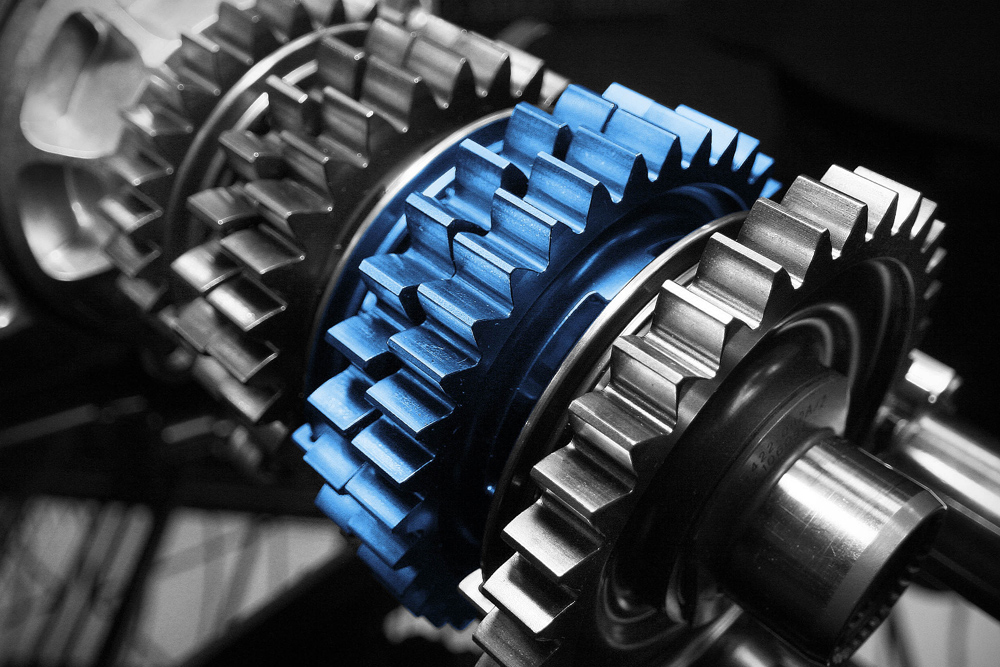

Process monitoring battery construction

Without laser welding, the implementation of electromobility on a large scale would be unthinkable! The laser is used in the construction of battery cells, in the joining of cells into modules, in the installation of modules in packages and also in the drive itself as well as in the construction of electric motors and power electronics. And no laser process without sensors! Therefore, the technology around optical coherence tomography, OCT for short, has a special role to play in this … >> read more

Process monitoring medical technology

Process Control Systems provides consistently reliable, high-quality welds including precision laser welding for medical products where material properties, functionality and dimensions must not be altered during laser processing.

All products in the medical field are subject to the strictest approval regulations and stringent quality requirements … >> read more

Process monitoring mechanical engineering

The applications of our technology for mechanical engineering are as varied as the requirements placed on them.

In any case, one thing is true – to ensure the reliable production of laser-machined workpieces, the industry needs repeatable and consistent technologies for monitoring laser processes. Depending on your needs, Lessmüller Lasertechnik offers you various solutions to choose from … >> read more

Process monitoring white goods production

In addition to automotive and medical applications, laser processing is widely used as a time- and cost-efficient method for welding commercial components in so-called white goods, i.e. household appliances such as washing machines, tumble dryers, refrigerators, freezers and dishwashers: from welding, control elements or electromechanical components to joining frame elements and stainless steel housings … >> read more