LASER WELD DEPTH MEASUREMENT

Precise weld depth measurement for stable seam joints

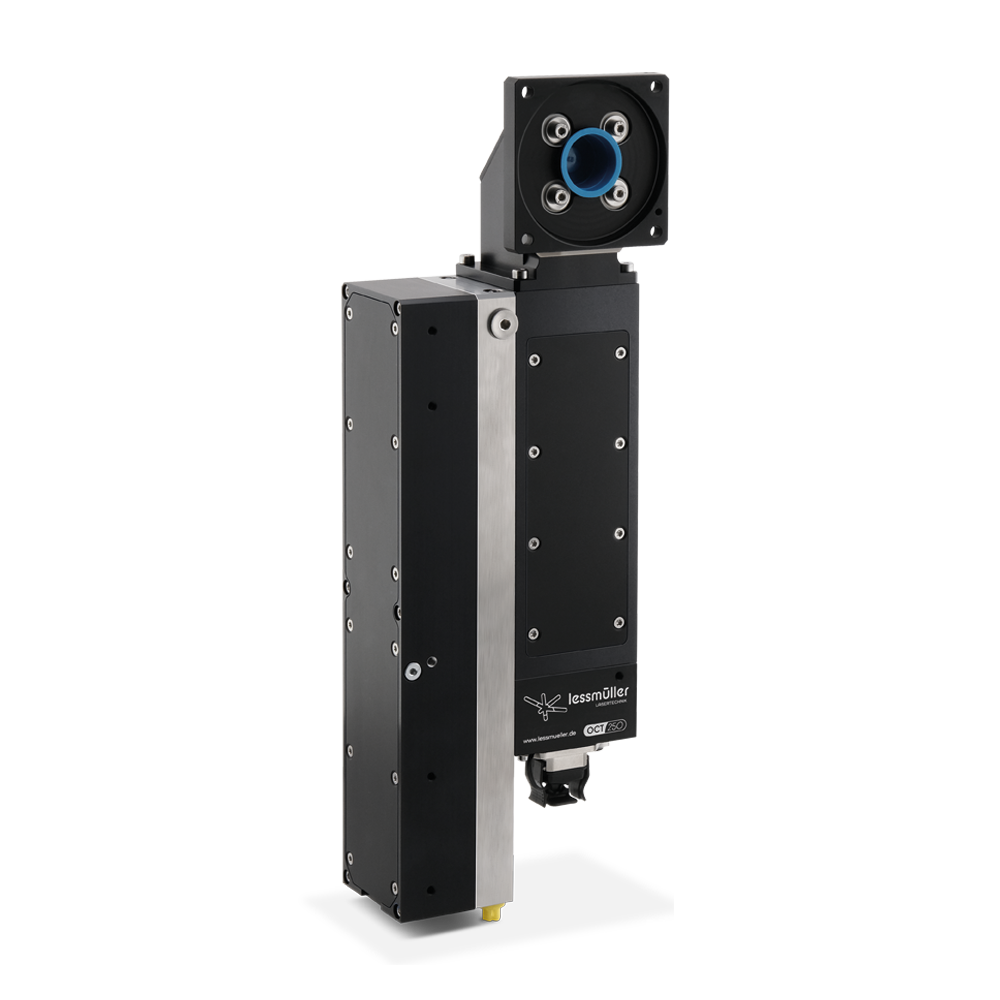

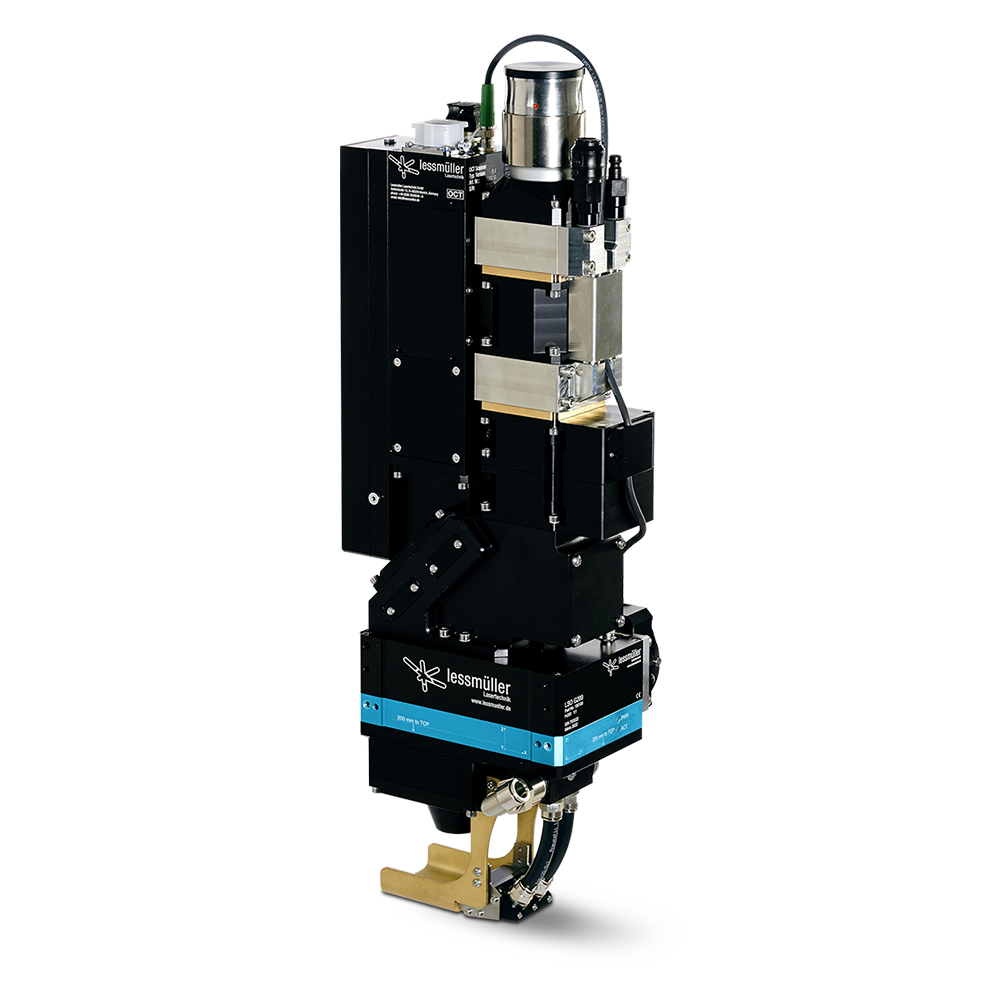

The OCT system from Lessmüller Lasertechnik, which is based on optical coherence tomography, offers the unique possibility of measuring the depth of the keyhole and thus the weld penetration depth during the welding process. The OCT measuring beam is collinearly coupled into the processing beam and directed to the deepest point of the keyhole. No other method succeeds in detecting the weld penetration depth in such an economical way.

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our

Datenschutz.

Monitoring the weld penetration depth provides crucial insight into the stability of the finished weld and the stability of your process.

The nature of the keyhole varies and depends on the process parameters and the materials used. Proven algorithms adapt the OCT measurement to the respective conditions and ensure reliable weld penetration depth measurement.

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our

Datenschutz.

All measurement and evaluation data of the OCT system from Lessmüller Lasertechnik can be stored in each case and thus enable complete traceability.

Lessmüller Lasertechnik also offers to examine your process for the possibility of welding depth measurement in our in-house laboratory. Please contact us.

At home in many industries

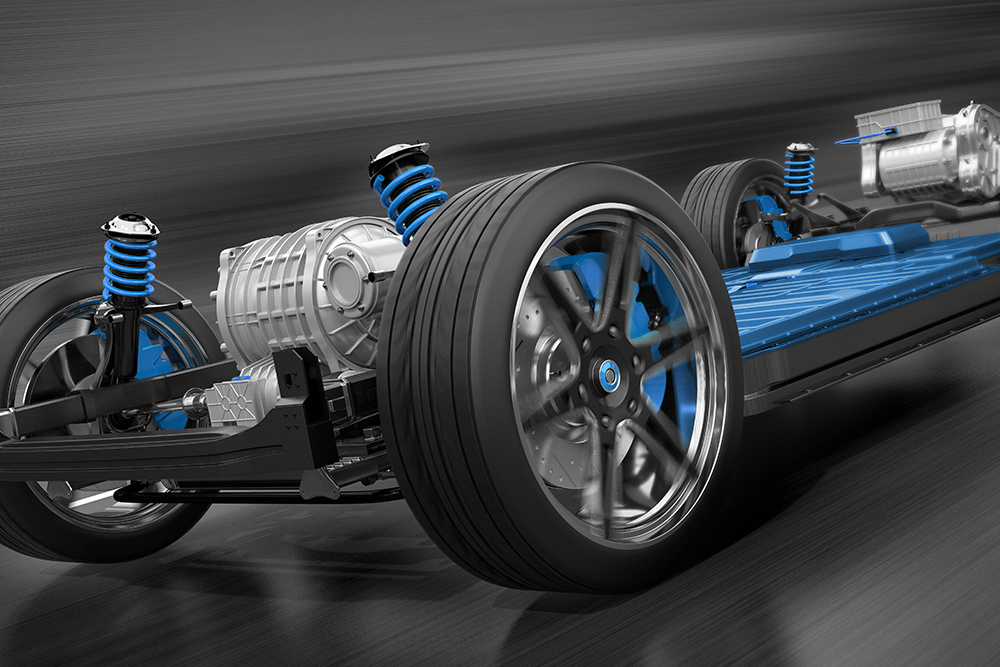

Process monitoring powertrain

Various techniques have found industrial application in automotive series production to observe laser processing in the field. Among them:

OCT – Optical Coherence Tomography

WELDEYE – Camera monitoring with ext. illumination

Laser processing heads equipped with OCT (optical coherence tomography) offer a … >> read more

Process monitoring battery construction

Without laser welding, the implementation of electromobility on a large scale would be unthinkable! The laser is used in the construction of battery cells, in the joining of cells into modules, in the installation of modules in packages and also in the drive itself as well as in the construction of electric motors and power electronics. And no laser process without sensors! Therefore, the technology around optical coherence tomography, OCT for short, has a special role to play in this … >> read more

Process monitoring e-mobility

The electrification of cars and aircraft with the aim of significantly reducing emissions and noise places increasing demands on laser processing. Welding has to be faster, more precise and more efficient. In the context of e-mobility, optical coherence tomography OCT from Lessmüller Lasertechnik is at the forefront as a technology for quality assurance in order to meet the high requirements when welding components for electric drive units. OCT offers for this … >> read more