Medical technology

Medical technologyWELDING MONITORING SENSORS MEDICAL TECHNOLOGY

Quality assurance for maximum patient safety

Process Monitoring Systems provides consistently reliable, high quality welds including precision laser welding for medical products where material properties, functionality and dimensions must not be altered during laser processing.

All products in the medical field are subject to the strictest approval regulations and stringent quality requirements. This applies to devices, instruments and especially to implants.

Typical is the DIN EN ISO 13485, which regulates a great deal in welding monitoring sensors.

Therefore, laser welding is the optimal joining process, as it is already extremely stable and safe itself. By using suitable monitoring sensor technology, the process reliability and quality of the products can be increased and secured even further.

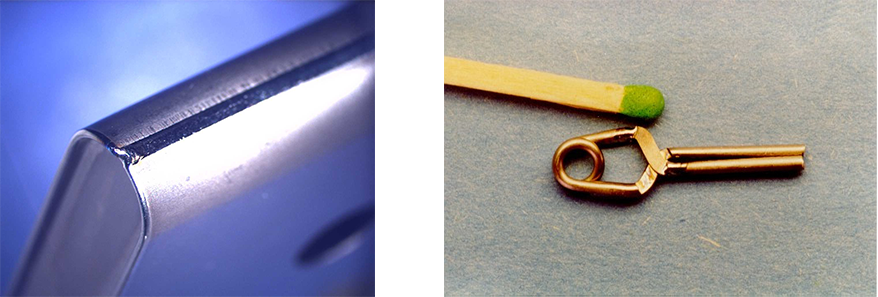

Optical Biopsy Forceps Aortic implant

Pacemaker Aneurysm Clamp

Lessmüller Lasertechnik offers manufacturers of laser welding systems in the field of medical technology the possibility of optimizing processes by means of optical sensors and automated process monitoring (Welding monitoring sensors) in order to produce functional parts and assemblies in excellent welding quality that also meet the highest requirements of medical technology.

It is of utmost importance that the welds of medical implants and device parts are of the highest quality to ensure maximum safety for the patient.

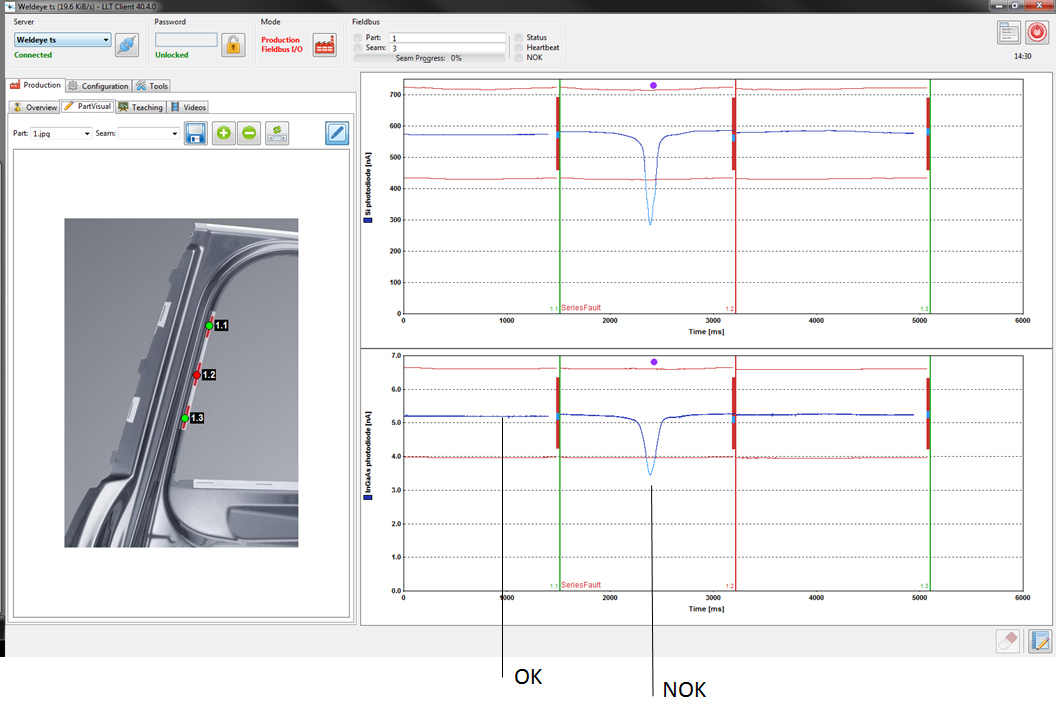

For process control in the manufacture of medical devices, the use of photodiode WELDCHECK systems proves to be particularly advantageous.

Screenshot shows error detection with WELDCHECK

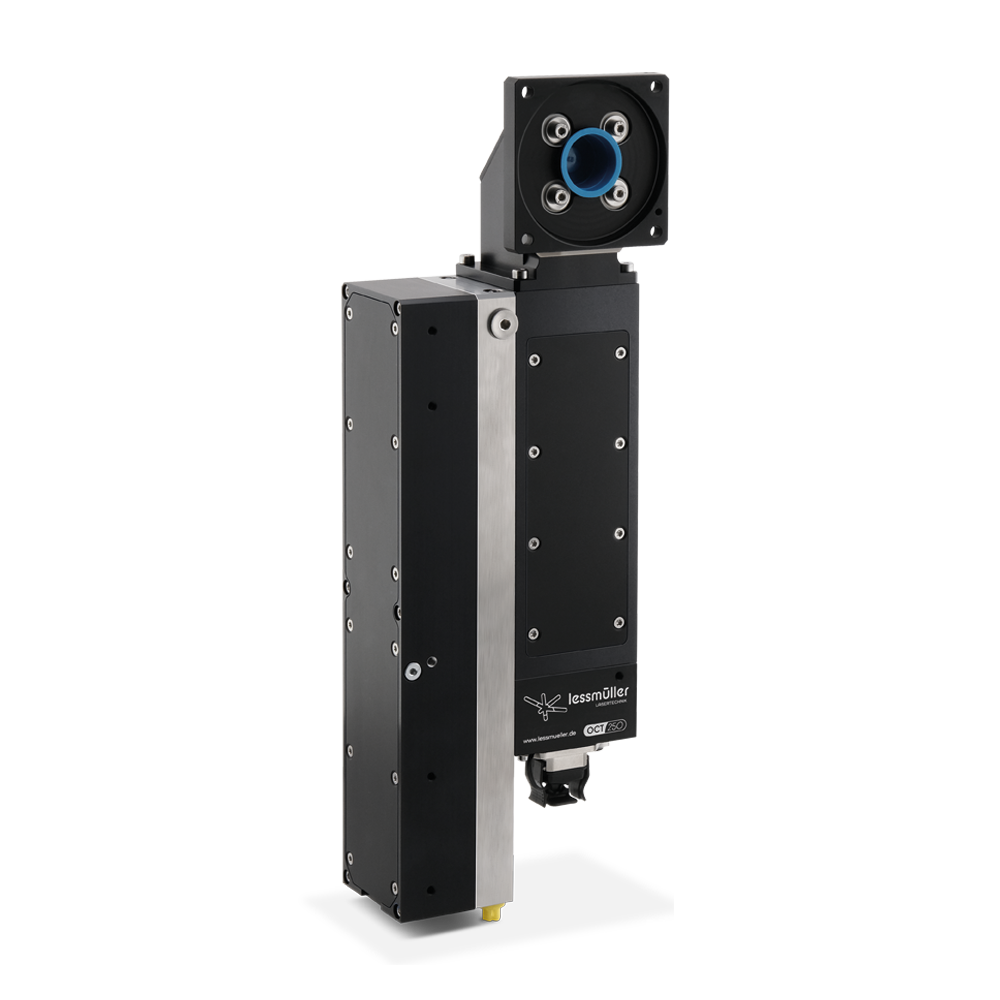

Advanced capabilities are offered by laser welding with OCT (a process based on optical coherence tomography), which is able to deliver accurate, repeatable and reliable joints for medical devices and assemblies. OCT is available as a stand-alone solution or for integration into production lines. It handles the pre-, intermediate- and post-processing steps and enables to meet the stringent process control and documentation requirements for laser welding of medical parts.

You don’t find your business here? No problem…